Gas Turbines/HRSGs/Simple Cycles

Gas turbines (GTs) are versatile power generators that have fast start up, efficient operation, and low emissions. They are used to meet peak power demands, with quick response, and when natural gas prices are low they can be excellent choices for base power. Simple Cycle designs use only a GT followed by catalysts to remove pollutants such as CO and NOx.

Heat Recovery Steam Generators (HRSGs) are also used downstream of GTs to efficiently utilize exhaust gas heat. The gas travels through steam tube banks to generate steam for a turbine or process equipment.

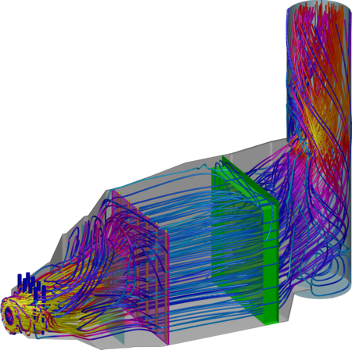

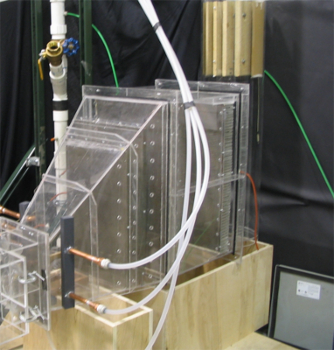

Flow and heat transfer characteristics within a Simple Cycle, Combined Cycle, or HRSG are critical to its performance. Airflow Sciences Corporation utilizes our flow modeling expertise to optimize the heat transfer to the tube banks, the velocity and temperature profiles through the CO and NOx catalysts, the duct burner position and design, design of the AIG or tempering air system to reduce ammonia slip, as well as the overall pressure loss.

Utilizing our 3D Probe Data Acquisition System, ASC can test the flow field downstream of the turbine or upstream of catalysts to ensure any flow control devices are working as intended. The data can also be used to improve heat rate per the EPA 111(d) standard.

Airflow Sciences can also help design the layout for new plants. Plume dispersion and general external modeling of the full site aids in stack, GT inlet, and condenser placement. The goal is to avoid negative interaction between stack exhaust and GT/condenser intakes that would lead to efficiency reductions.

Read the 2018 Fall newsletter article "HRSG Ammonia Injection Optimization" for a CFD application.

Learn more about CFD modeling for Simple Cycle Systems on our YouTube channel.

Learn more about CFD modeling for natural gas dispersion on our YouTube channel.