Stacks

Flow modeling and testing of smokestacks is extremely important. Though it seems like a simple tube, the stack is the final part of the gas flow path where many pieces of expensive instruments are located:

- Gas flow rate sensors

- NOx, SO2, mercury, particulate monitors

Flow modeling is used to ensure uniform, controlled flow exists at these instruments, so accurate measurements can be reported to EPA. Airflow Science's stack testing equipment is extremely accurate, so that plant systems can be correctly calibrated to EPA standards.

CFD and physical flow modeling can also be applied to wet stacks. To optimize liquid collection systems and drains, the added complexity of droplet impingement, condensation, and evaporation must be analyzed.

External flow modeling outside the stack can assist with plume dispersion analysis and examination of problematic flow conditions due to winds or surrounding environmental features.

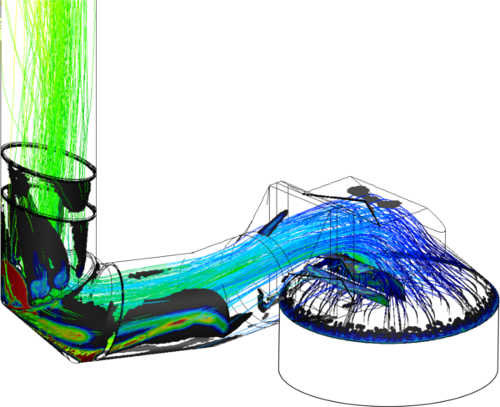

CFD flow model of stack

CFD flow model of stack Wet stack droplet trajectories

Wet stack droplet trajectories

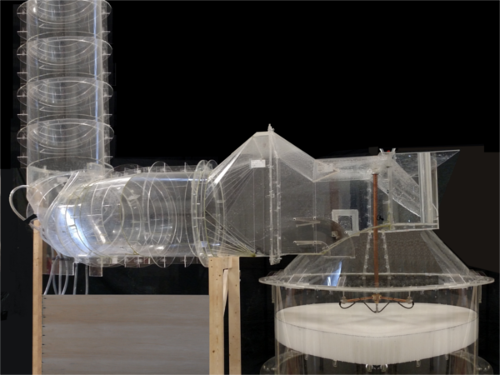

Physical flow modeling

Physical flow modeling