Controlled Cooling

Forged parts are often machined before heat treating for final hardness and microstructure. For the machining step, low hardness is desired in order to preserve tool life. This had traditionally been accomplished by annealing the forged parts prior to machining. The energy associated with that extra heating cycle is significant, and represents an additional cost, particularly if the annealing is performed by an outside heat treater.

If the newly forged parts are cooled at the appropriate rate after leaving the forge, that extra step can be eliminated, which also reduces work-in-progress inventory.

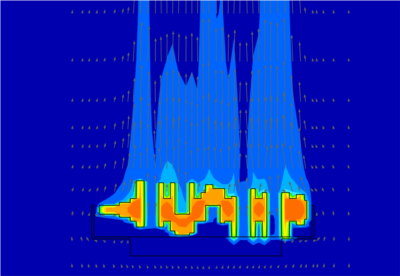

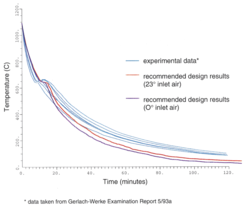

Airflow Sciences developed a controlled cooling process for a crankshaft forging line at Ford Motor Company that utilized the buoyant energy of the heated air to drive the flow through the system. CFD simulations of the system showed that the initial design would have allowed the parts to crankshafts to cool too quickly. The final design achieved the desired cooling rates, and was shown to be insensitive to various production upset conditions.