Large Particle Ash

Airflow Sciences Corporation has been involved in over 100 projects focused on the modeling and design of devices that capture LPA (Large Particle Ash) and protect air preheaters and SCRs from pluggage.

Large Particle Ash (LPA) that is allowed to travel downstream beyond the economizer hopper can cause pluggage issues in both the air preheater and SCR.

This pluggage can cause:

- Increased system pressure loss

- Large cleaning costs

- Forced outages

- Reduced efficiency of the catalyst

- Increased NOx

- Increased ammonia usage

- Accelerated catalyst de-activation

- Erosion of the catalyst

Flow Modeling and Testing Optimizes SCR Performance

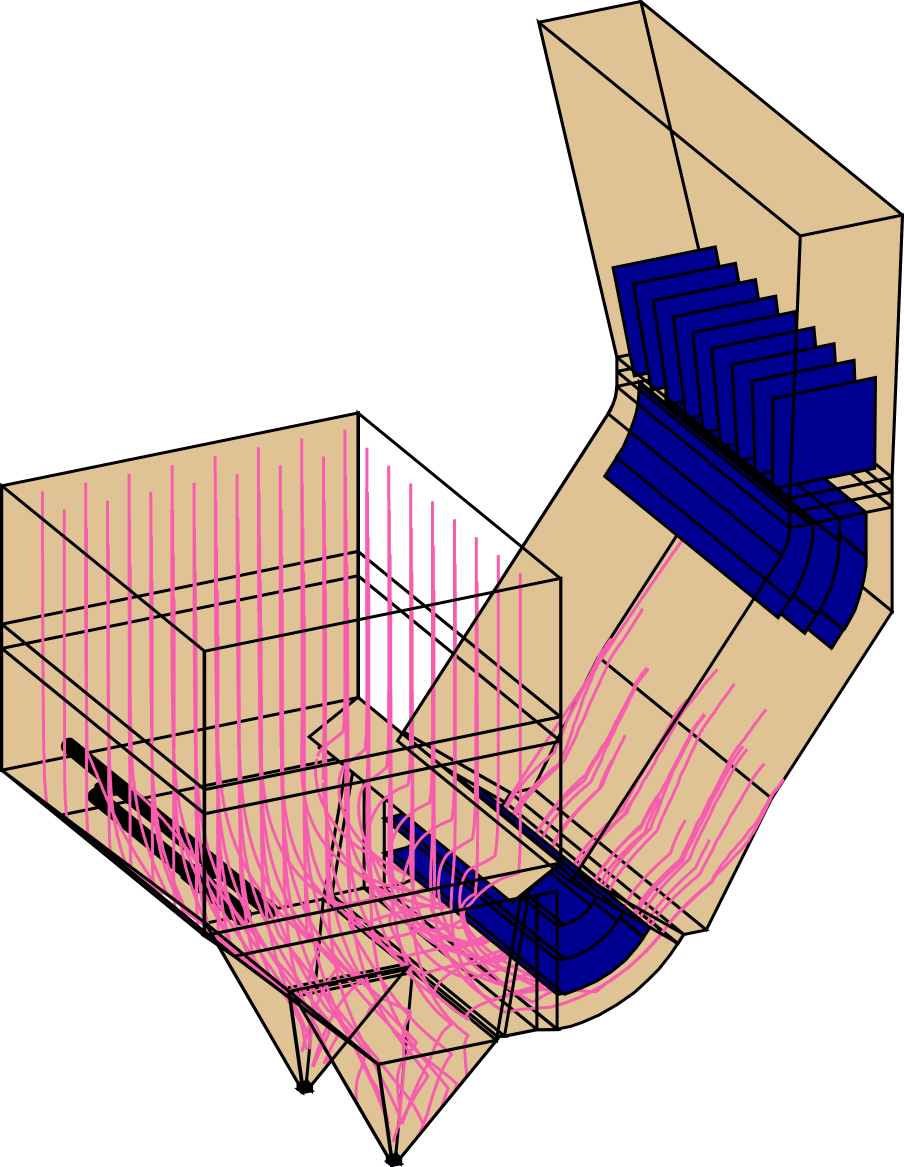

Airflow Sciences utilizes proprietary CFD methods to obtain the most accurate predictions of LPA behavior. The models are used to design aerodynamic baffles and LPA capture screens. Without careful modeling and prediction of gas velocities and particle trajectories, baffles will be inefficient and screens can erode quickly.

Airflow Science Corporation's CFD modeling:

- Analyzes which approach will works best: baffles, screens or a combination of both.

- Incorporates the proper drag, rebound, and specific gravity features of popcorn ash.

- Predicts the percentage of ash capture in the economizer hopper.

- Computes trajectories for various particle sizes.

- Compares pressure loss versus capture efficiency; modifications are designed to balance maximum capture efficiency with minimal pressure loss.

Field Testing

- ASC's field testing services provides on-site measurement of LPA flow rates and SCR velocity patterns.

- Use of ASC's online inspection camera can help detect ash build up problems on catalysts, LPA screens, and other internal elements.

For more information about SCR catalyst pluggage reduction, please review this 2010 MEGA Symposium presentation.

Learn more about capturing large particle ash on our YouTube channel.