Refined engineering solutions for the refinery industry

Airflow Sciences Corporation has performed CFD modeling, laboratory experiments, and field testing for the Oil & Gas industry for over 25 years. Our simulation and testing expertise can help solve your complicated engineering problems, enhance thermal performance, reduce pollution emissions, and increase process output.

Equipment and Processes:

Project Goals:

Our Engineering Services for the Oil and Gas Industry

CFD Modeling

![]()

We use Computational Fluid Dynamics (CFD) to improve process performance. CFD simulations can easily assess design modifications and predict flow, heat transfer and species concentrations throughout an entire system.

Field Testing

We help you gather key performance data such as temperature, pressure, and velocity for a wide range of process equipment. Our skilled engineers and technicians perform on-site testing at your facility with state-of-the-art testing equipment.

Lab Testing

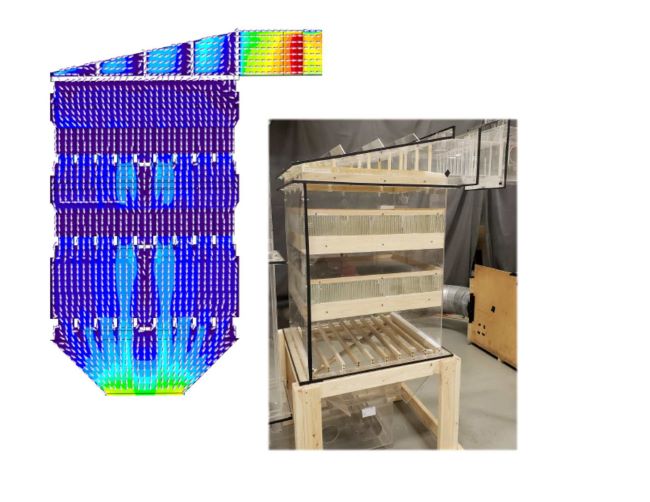

![]()

We create custom lab-scale models to evaluate a new or existing systems. In our dynamic laboratory, we can test a variety of flow conditions and scenarios. Lab testing can be combined with CFD modeling to investigate a process even more thoroughly.

Often our clients find it beneficial to utilize a combination of our services for their custom projects. Below is an example of a new SCR being evaluated through CFD modeling and tested in our lab, prior to implementation at a refinery site.

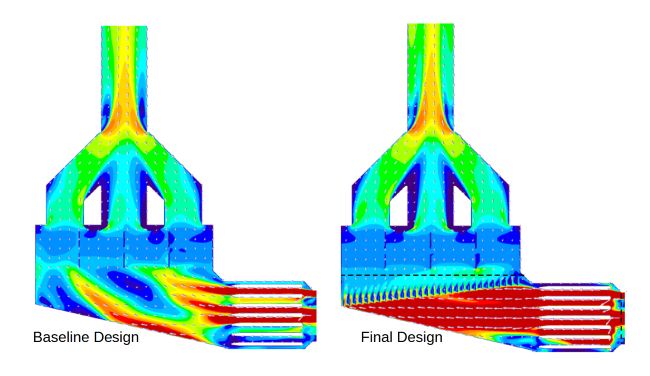

CFD models can also be used on their own to assist with design decisions in the planning stages. In this example of a WHRU, the Airflow Science's team was able to show a final design with the best flow uniformity.

Learn more about CFD modeling for the oil and gas industry on our YouTube channel.