Mining Industry

ASC has been serving the mining industry for over 20 years. Our flow modeling and field testing expertise can help reduce operational costs, improve equipment performance, and increase the overall throughput of many aspects of mining operations. Flow modeling and testing can be applied to multiple stages of the process, from extraction all the way through transport of the final product.

Some CFD applications in the mining industry are featured in ASC's VBlog and Blog.

CFD Modeling Services

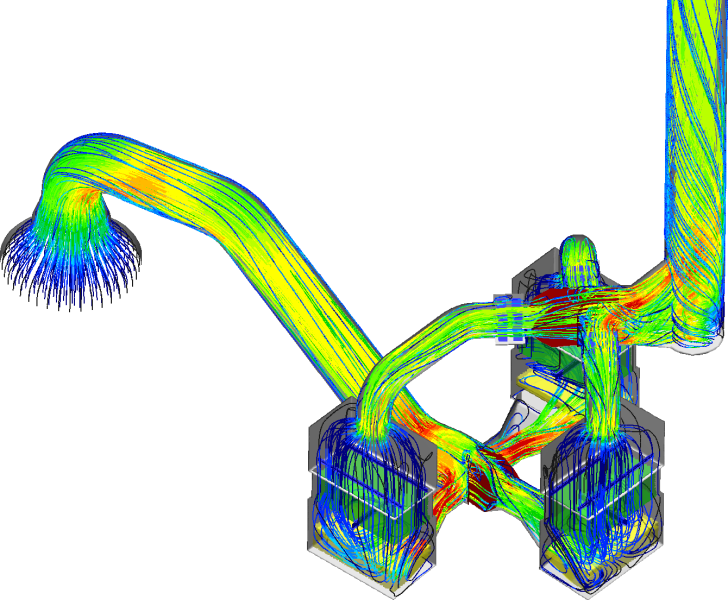

CFD flow modeling can provide critical information about gas and particulate flow both in and around the entire mining complex. External flow models featuring different wind speeds and directions take into account the specific terrain of the complex, including tailing piles. These models can also track plumes from stacks and vents, including particulate matter and combustible or toxic components. For processes that are prone to dust creation such as conveyor transport, crushing, and mixing, models can reveal the best way to minimize respirable dust including PM10 and PM2.5.

Mining ventilation systems can also be optimized with CFD, including both dust capture and air heating and cooling. CFD modeling is also beneficial in heat transfer processes such as smelting and thermal drying. Models can help achieve more uniform heat transfer and ensure product consistency.

For mining operations that include on-site power generation, Airflow can provide meaningful flow analysis for pollution control equipment like electrostatic precipitators (ESP), baghouses, and scrubbers. This equipment can be optimized to save costs, maximize collection, and meet environmental targets.

External Flow Patterns Over a Tailing Pile

Physical Modeling Services

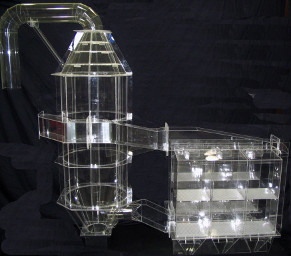

In addition to computational models, ASC can produce laboratory (scale) models to analyze complex flow conditions. Physical models are often used alongside computational models to provide additional insight and optimization of flow conditions—a "belt-and-suspenders" type of flow analysis.

Field Testing Services

Field testing can be critical to ensure that key equipment in the mining complex is operating as intended. Using highly reliable test equipment, our expert engineering and technical staff can provide online inspection services (at temperatures up to 750 degrees F) as well as measurement of velocity, temperature, and particulates.

- External Flow

- Ventilation

- Fans

- Ducts

- Plume Dispersion

- Dust Mitigation

- Sprays & Injections

- Furnaces/Burners

- Piping Networks

- ESPs

- Cyclones

- Pressure/Pressure Loss

- Velocity

- Temperature

- Sound

- Wind Speed/Direction

- Particulate

- Flow Rate

- Stack Emissions