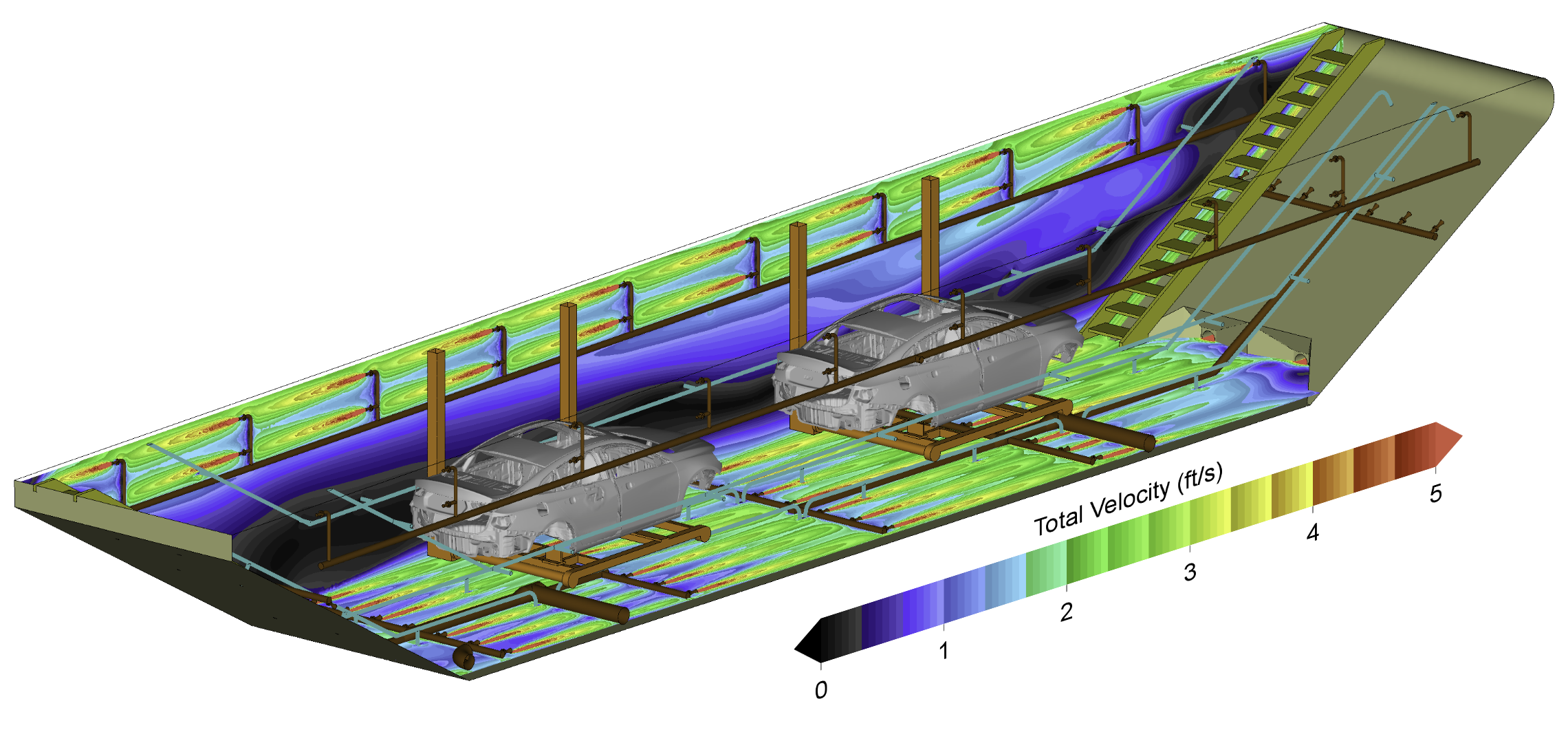

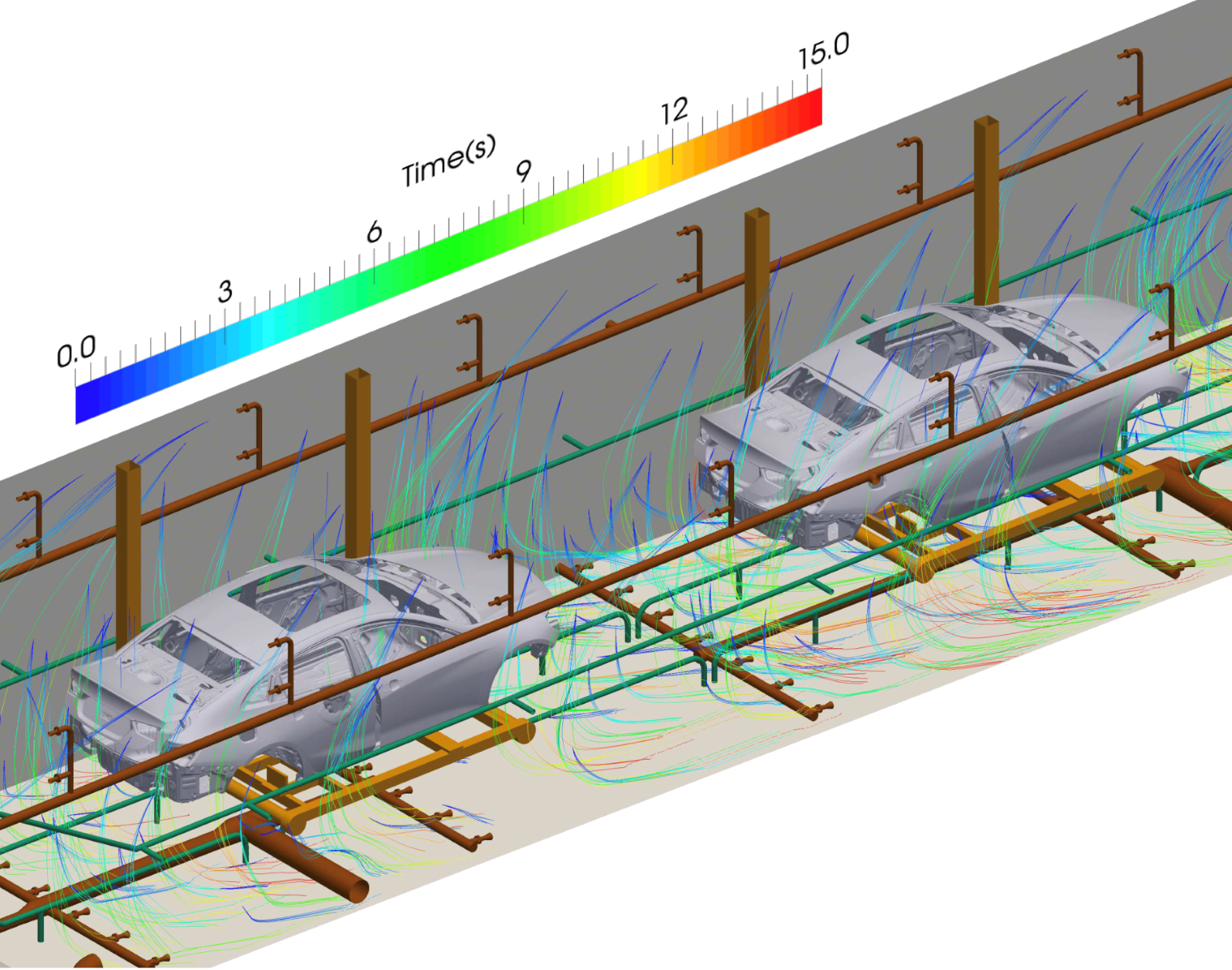

Liquid and Particle Flow in Dip Tank

Dip tanks are used in the automotive industry to deposit coatings and paint onto auto bodies. In order to ensure good coverage and prevent the paint particles from settling on the bottom of the dip tank, the fluid/solid mixture is pumped through a number of eductors creating a circulation pattern within the tank. CFD simulations can be used to assess the effectiveness of the mixing for a given eductor layout and the rate of particle impacts on the auto body surfaces.