CFD flow modeling of grow rooms or industrial warehouses is an effective tool for improving HVAC systems and ventilation throughout the facility. CFD results can be used to develop an optimized, cost-effective system that balances temperature and humidity profiles with minimal pressure losses and to confirm specification ranges for temperature or other attributes.

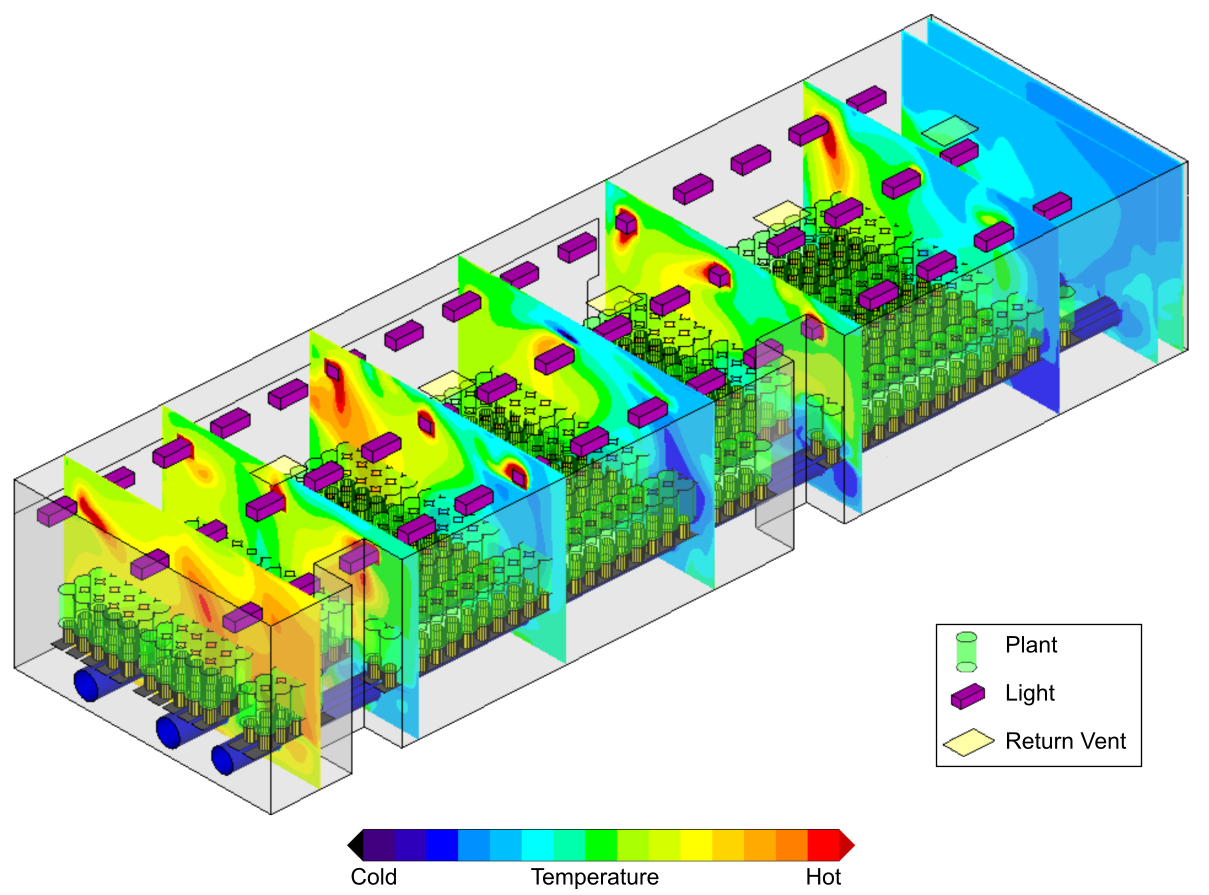

The ventilation system for this grow room consisted of three fabric ducts that ran underneath the tables that hold the plants, along with return vents in the ceiling. The CFD flow model included the heat sources of the lights and outside walls, as well as the added humidity from the plants.

The CFD results for the initial ventilation system design indicated that one end of the room was warmer than the other. The ability to virtually change any parameter (from flow rate to duct location to plant layout) individually or in combination, provides an efficient means of optimizing the air flow throughout the entire facility. The result of this analysis is a more consistent product.

ASC also has experience with experimental testing for grow room fans (see page 6 of our recent Newsletter) and field testing for velocity and thermal mapping of grow room flow patterns.

Some CFD applications for grow room design are featured in ASC's VBlog.