Reducing Drag for the Rail Industry

by Dr. Kevin Linfield, P.E., P.Eng.

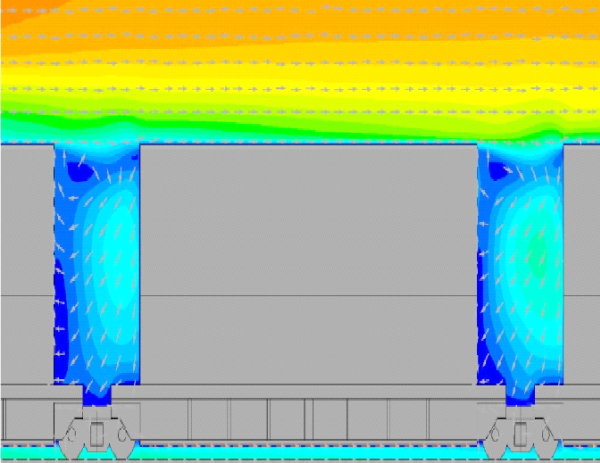

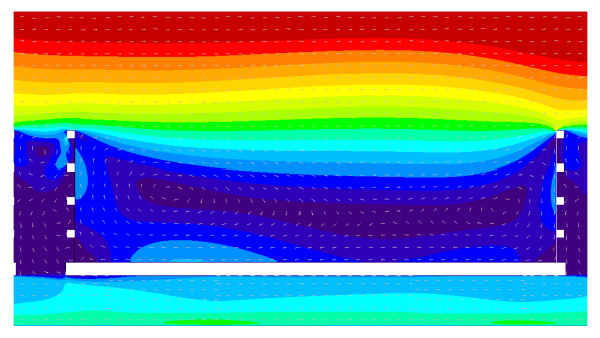

Open-top bulk commodity carriers, such as gondola or hopper cars, experience high drag while traveling empty back to the mine. This drag increases fuel usage, resulting in higher operational costs and more greenhouse emissions.

Since the 1970s Airflow Sciences Corporation (ASC) has been studying methods to reduce this drag using engineering analysis, wind tunnel testing, and Computational Fluid Dynamic (CFD) modeling. The shape of the top of the car plays a very important role in how the air enters, swirls, and exits the empty cavity. By calculating the forces exerted on the car and analyzing the leading and trailing edges, the drag of the car can be determined and often straight-forward geometry changes can result in a noticeable reduction of drag.

ASC recently investigated fuel savings on long trains traveling over hundreds of miles. Handbook calculations determined that an expected fuel savings of about 7% could be achieved. CFD modeling combined with wind tunnel testing predicted a 15% decrease in the drag on the train by implementing geometry changes, including an "airfoil" shape. Discover more information about Airflow Sciences involvement in the railroad industry in the links below.

More information on ASC involvement in the railroad industry, including our five (5) US patents, can be found in the railroad industry section.

Learn more :