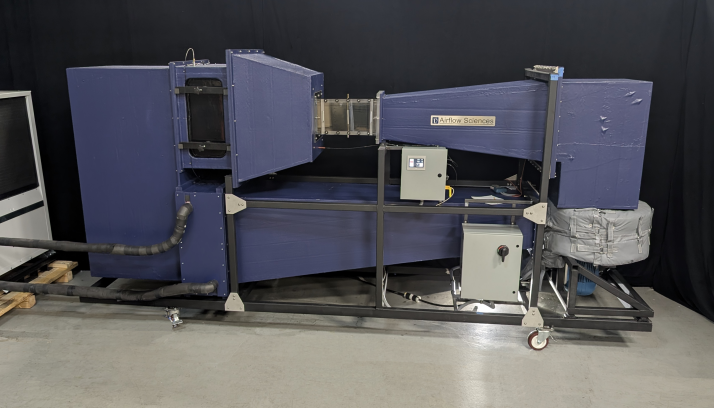

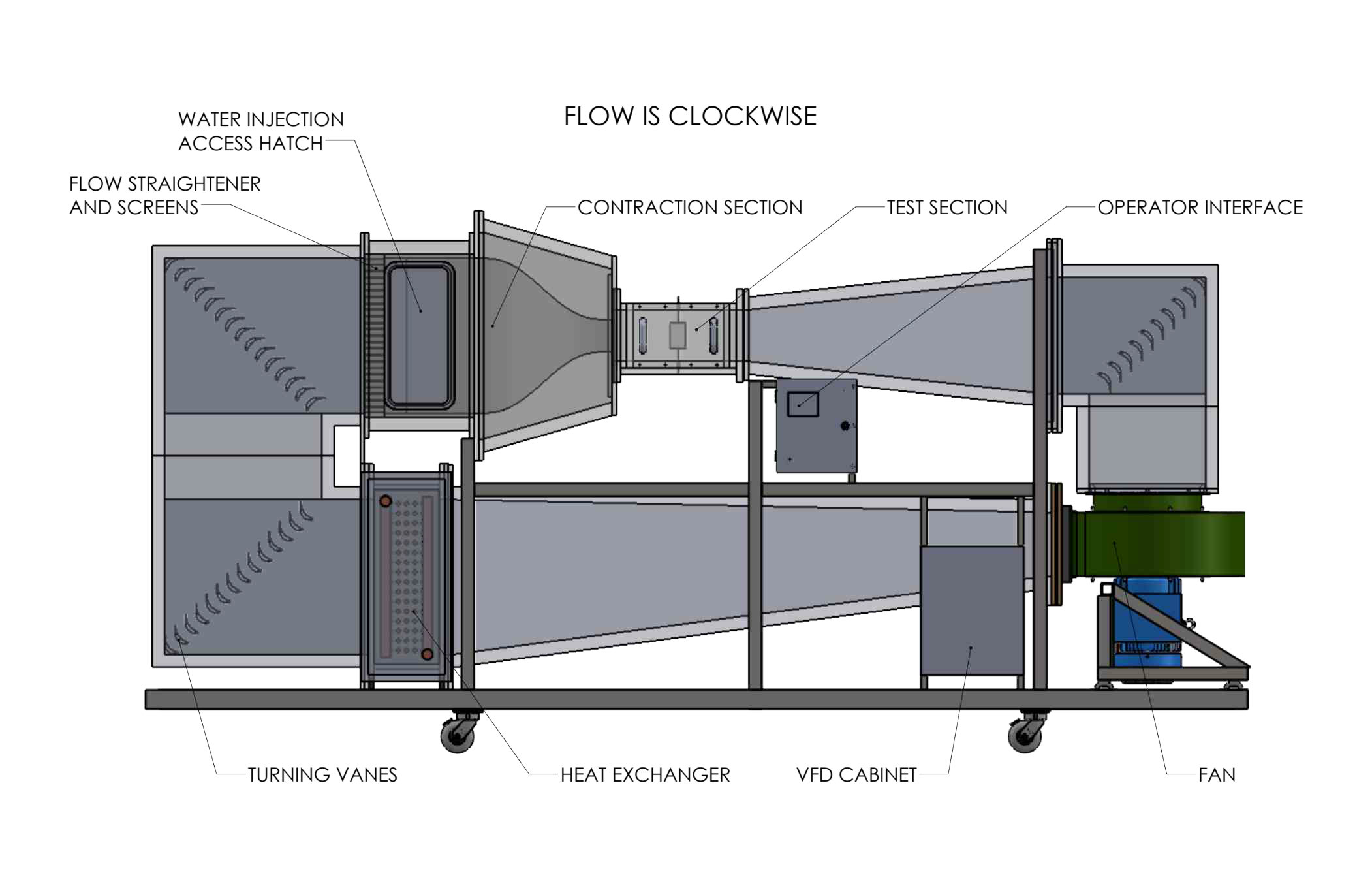

Brr! This wind tunnel researches sub-zero temperatures and was custom-made for the Polymer Surfaces Interfaces Group at the University of Michigan. The tunnel design allows the integration of a water spray system into the cold air loop for simulating ice-accumulation and will be used to develop advanced ice-repellent coatings.

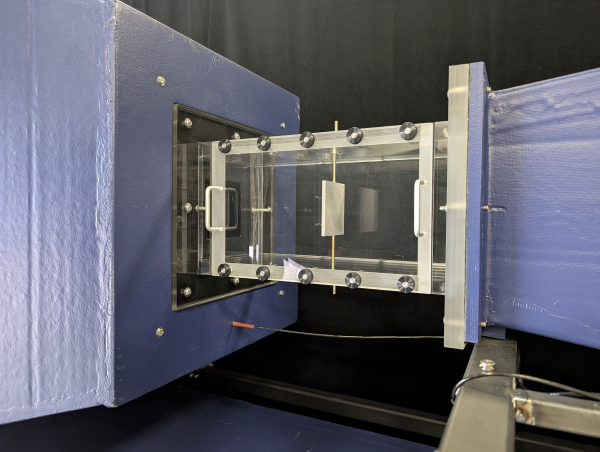

The PSI research group is using polymer coatings to address the problem of ice accumulation on surfaces. The advances made in this field could be particularly useful for surfaces such as airplane wings, windshields, or even solar panels. This cold air wind tunnel supports the unique testing performed by the PSI research group, which involves small test plates that are placed in a mist jet moving at speeds of up to 60 m/s (130 mph). The air temperature in the tunnel can reach -20°C.

This wind tunnel is all about thermal performance. It was engineered to minimize pressure losses and optimize fan performance, limiting heat generation from the fan. The duct walls are constructed from insulating material, and chilled air is achieved through a built-in heat exchanger with an external chiller. The system controls modulate the temperature and fan speed based on user inputs.

Wind Tunnel Components

- Variable speed fan with insulated casing

- Ethylene glycol heat exchanger and an external chiller with water drainage system

- Insulated ductwork for high cooling efficiency

- Flow controls to minimize pressure losses

- 5"x5" jet into 8"x8" test section with custom mounting system for test samples

- Touchscreen user interface with real-time data display and user controls