Liquid Quench Tanks

Liquid quenching provides the fastest cooling rates for any quenching process, and may be needed to achieve the desired hardness, especially for low-alloy steels. If not done with care, however, distortion and uneven material properties can result. CFD analysis of the quench tank can be used to improve the performance of existing quench facilities and can ensure that new quench facilities meet the target performance metrics.

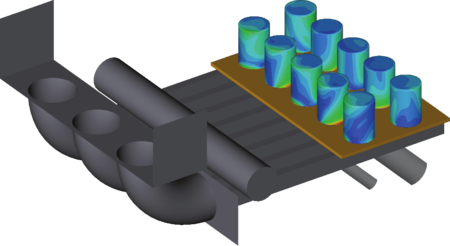

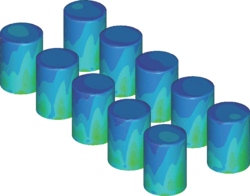

The images above show the heat surface heat transfer coefficients on a set of generic parts before and after modification to a quench tank design. Further information can be found in a presentation given at the ASM Heat Treat Conference.

This video shows information about the pseudo steady state cooling of a small heated surface with quenchant oil flowing over the surface. The starting surface temperature is well above the boiling point of the quenchant at the start of the video. A collection of information is shown including the location of the boiling curve (moving dot) synchronized with still images of the boiling activity. The video is time elapsed and the actual test takes about 20 min.