Metal Processing

Many metal processing operations involve air/gas/liquid flow and heat transfer, and the design of that equipment can have a strong effect on the qualities of the finished product.

Airflow Sciences has worked on the following processes:

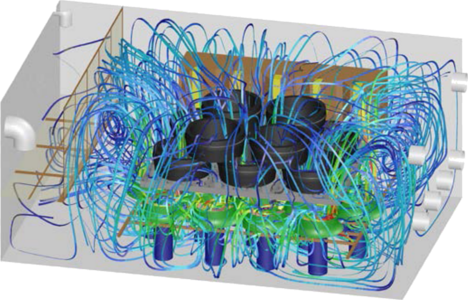

Path lines within a quench tank

Path lines within a quench tank- Annealing

- Age Hardening Furnaces

- Solution Treating Furnaces

- Atmosphere Carburizing Furnaces

- Basic Oxygen Process (BOP) Hoods

- SBIR Boiling Research

- Controlled Cooling

- High Pressure Gas Quenching

- Intensive Quenching

- Liquid Quench Tanks

ASC also received Phase I and Phase II SBIR awards from the Air Force Research Laboratory (AFRL) to develop improved CFD-based boiling models for use in liquid quenching simulations. That work will help in the determination of bulk residual stresses in quenched parts, leading to lower cost and higher quality parts.