Engineering & Fluid Dynamics Case Studies

What kind of solutions does Airflow Sciences Corporation offer?

Since our clients come from numerous industries across the globe and their problems are solved using a variety of engineering techniques, this can be difficult to define. But know that our applied science has made golf balls go straighter, vehicles more fuel efficient, beer more flavorful, potato chips crispier, power plants more efficient, and pollution control equipment operate better. In fact, we even helped the US Bobsled Team take a World Cup victory!

In short, we offer endless solutions to various industry challenges.

|

Rail Diesel Exhaust Analysis for Legal Cases As of 2021, Airflow Sciences Corporation (ASC) has consulted on eleven legal cases where the train operators’ exposure to diesel exhaust was evaluated. |

|

|

The Role of CFD in a Legal Proceeding In legal cases that rely on technical details, engineers are oftencalled upon to perform engineering analysis or testify as expert witnesses. |

|

|

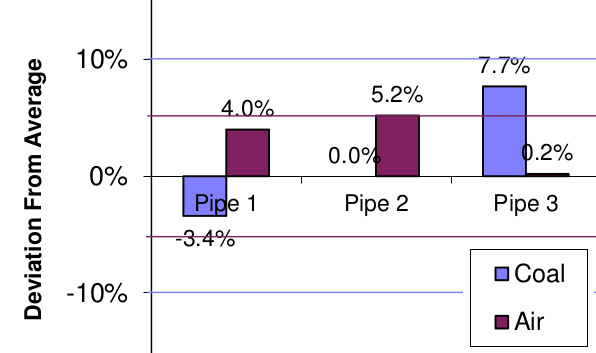

Air and Coal Balancing for Improved Combustion The air to fuel ratio is important for combustion efficiency. By adjusting the coal and air flow to within acceptable balanced standards, coal pipe balancing is achieved. |

|

Gas analyzer equipment is used to measure the SCR performance. Testing personnel then tune the AIG to minimize ammonia consumption. |

|

Simple Cycle Systems and HRSGs CFD flow modeling of simple cycles or HRSGs can improve uniformity of velocity, temperature, and ammonia, as well as minimize the pressure drop. |

|

V-22 Osprey Cabin Cooling System Upgrade A physical model of the HVAC ducting system of a V-22 aircraft was constructed in order to test the flow balance and to verify an improved duct design. |

|

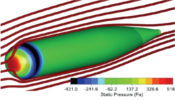

Helping Advance Ocean Research CFD analysis of aerodynamics was used to determine whether a long-range, high-speed vehicle was feasible based on current energy storage technology. |

|

Innovative Mixing Device Reduces Thermal Stratification in Ductwork A coal plant experienced temperature stratification in its pulverizer inlet ductwork. A CFD model was used to design and optimize an air mixer device. |

|

A physical model and CFD analyses were used together to generate a uniform velocity profile and provide consistent NOx ratios, despite severe stratification in the SCR. |

|

"Cold zones" in an ESP increased the risk of metal corrosion. A CFD model of the flow patterns was used to develop a customized mixer to reduce the thermal gradient. |

|

Coal pipe balancing can ensure that emissions are reduced and combustion efficiency is improved. Duct field testing of existing pipe geometry and subsequent analyses can optimize flow control devices. |

|

Particulate Emissions Reduction Flow distribution through particle collection systems has a major influence on pollution control. Flow control baffles designed for this ESP not only improved flow, but also minimized potential for flyash accumulation. |

|

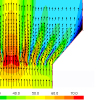

Vehicle Interior Heating & Cooling A CFD model simulated the radiative heat transfer from the sun, and the temperature of the vehicle interior was computed. The effectiveness of different glass types was quickly evaluated by changing glass transmission assumptions. |

|

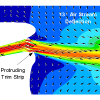

Panel Duct & Register Development Applied in conjunction with testing, numerical analysis techniques allowed our engineers to design panel duct systems with optimal flow balance. |

|

CFD analysis evaluated various defrost system designs. A time-dependent simulation showed the rate at which heat was transferred from the warm defrost air through the windshield glass and, finally, to the ice. |

|

Wind tunnel testing was used to evaluate improved helmet designs, greatly reducing violent drag forces on the Indy car driver. |