Heat Transfer using CFD Flow Modeling

As an alternative to physical modeling, ASC uses CFD as a cost-effective way to help clients reduce costly fixes, possible product loss, and unexpected results from trial and error. Through CFD modeling, ASC has solved a wide variety of engineering problems involving:

- Conduction and conjugate heat transfer

- Forced, natural, and mixed convection

- Heat transfer within fluids

- Heat transfer between fluids and solids

- Heat exchange through solids

- Thin surfaces

Project Examples:

BESS temperature management: Battery temperature increases significantly during peak discharge cycles, causing possible overheating issues which can result in unit failures or fires. Learn more with a short video on how CFD can be used for thermal management design.

This animation shows blue cold air feeding directly to the equipment intakes.

Commercial bakeries: One bakery found that the ovens used to bake pies were consistently producing half-burnt product that were unsalable. Knowing that trial and error could continue to cause a larger financial risk to the bakery, ASC took on the task to determine the failing and correct the heat transfer issue within the ovens. A short video on CFD Modeling for Commercial Pie Baking can be found here.

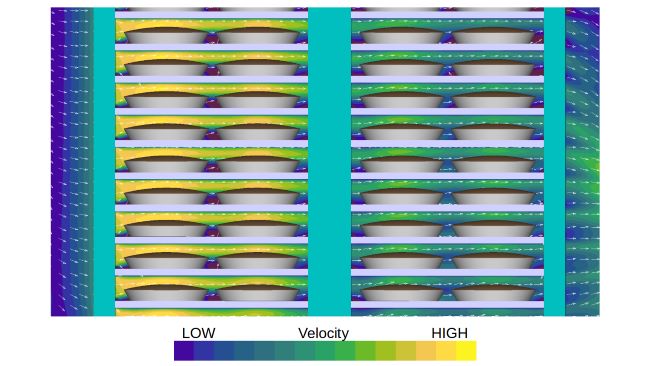

The results of CFD modeling shown here illustrates where the velocity of hot air is highest in the oven,

leading to hot zones ... and burnt pies.

Cryptocurrency mining: ASC has been tasked over the past few years to help large Bitcoin miners optimize the HVAC systems of their facilities. Although cooling systems are usually in place, the heat released from GPUs/CPUs can be enormous and still has the ability to slow down hashrates or even shut down operations. Read more from our blog, Flow Modeling for Cryptocurrency Mining. Watch a short video of how ASC has modeled a Bitcoin mining facility with AzoreCFD.

Temperature inside an enclosure.

Rotary air pre-heater flow problems in power plants: Rotary air pre-heaters in power plants are used to extract heat from hot flue gas for use in pre-heating the cold air that feeds into the boiler. ASC, using AzoreCFD, analyzed the temperature variation. View a short video, featuring Dr. Kevin Linfield on Thermal Mixing of Rotary Air Heaters with CFD.

Thermal mixing downstream of a rotary air heater.

Uniform Heat Treatment : The best results of your heat treatment comes from the uniformity of the heat being used. Using CFD, ASC can look at not only the part being treated, but also the fluid around it, giving the best results without the cost of preforming multiple physical trials. View a short video from Dr. Kevin Linfield here on heat treating.