Selective Catalytic Reduction

In an effort to reduce emissions of nitrous oxides, many power plants, refineries, and industrial facilities are installing selective catalytic reduction (SCR) systems. SCRs work by injecting ammonia into the flue gas upstream of a fixed catalyst. The NOx and ammonia react in the presence of the catalyst to produce nitrogen gas and water.

In order for an SCR to work efficiently, it is important to achieve a uniform velocity profile, a uniform temperature profile, and a uniform ammonia concentration at the upstream face of the catalyst. Both physical modeling and computational fluid dynamics (CFD) can be utilized in order to achieve these goals.

Physical Modeling

A fan draws air through the 1/12th scale physical model of an SCR and its associated ductwork. A tracer gas is used to simulate the injection of ammonia. Velocity measurements are then taken at the catalyst face with a hot mandrel probe, while a gas sampling probe is used at the same location to determine the tracer gas concentration model. The model is used to optimize the system design for maximum NOx removal with minimum ammonia usage and pressure drop.

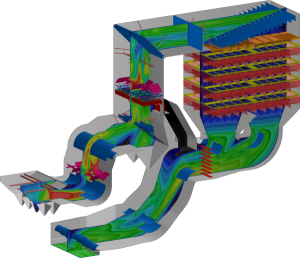

CFD Modeling

Numerical simulation via CFD is also used to understand flow patterns and optimize SCR design. The complex geometry due to mixers, internal structure, and flow devices require high-quality CFD meshes in order to obtain accurate results. ASC engineers are experts, and hand-build the meshes to avoid pitfalls associated with auto-mesh techniques.