Air Heaters

Air heater performance is important to heat rate, coal drying, and APC equipment.

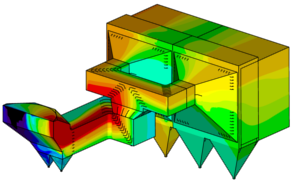

The CFD results below show poor ash capture, resulting in air heater flyash pluggage. ASC modifications at this plant resulted in 100% ash capture for large particles (>500micron). The plant has realized a savings of $200,000 per year by eliminating forced outages for air heater cleaning.

CFD flow models are used to diagnose and correct air heater (AH) problems, including:

- AH pluggage caused by local low temperature zones in the cold-end baskets (rotary) or in certain tubes (tubular),

- AH inleakage resulting in reduced heat rate and increased flow volume to APC equipment and fans,

- AH outlet temperature gradients that adversely influence ESP performance and sorbent pollutant absorption.

Rotating AH Flue gas temperature distribution

Rotating AH Flue gas temperature distribution

Tubular AH pluggage issue

Tubular AH pluggage issue