CFD Applications in the Mining Industry

by Kevin Linfield, Ph.D., P. Eng., P.E.

Extracting ore or minerals from the ground has become a complex procedure. Gone are the days of simply picking up gold nuggets in a stream. Different techniques are used for surface mines compared to those underground. The mining process, from extraction to a final salable product touches upon transportation and processing - which may include smelting, crushing, mixing, and refining. Mines often include their own power plant or boiler, and these facilities often feature pollution control equipment such as ESPs, baghouses, and scrubbers. With many of these steps, computational fluid dynamics, or CFD modeling, plays an active role in process optimization.

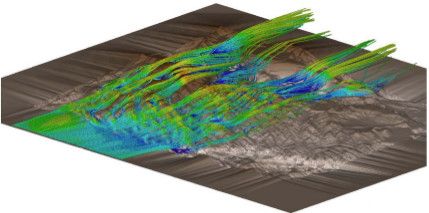

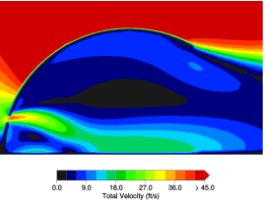

External Flow Over Tailing Pile

External Flow Around Facility

Computer simulation of external flow fields help determine localized effects of the wind. High winds cause particles from operations or tailings to be dispersed in unwanted areas. Some external flow modeling may include areas of many square miles. The force of the wind may cause structural damage in and around buildings or equipment as shown in the figure above.

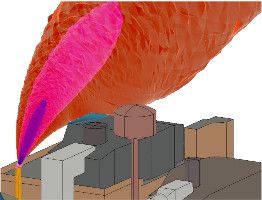

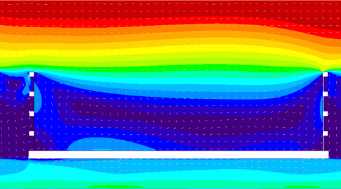

Plume Dispersion Over Entire Site

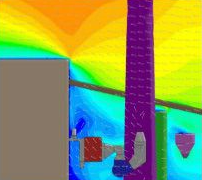

Plume Dispersion Over Single Stack

Air quality dispersion modeling tracks gases and particulates emanating from stacks and vents. Plume behavior depends on many environmental variables such as temperature, wind speed, and wind direction. Ensuring that the stack discharge avoids any air intakes is often part of a plume study analysis, as well as tracking combustible or toxic discharges. With diesel-powered mining equipment, the venting of exhaust is often analyzed with CFD modeling.

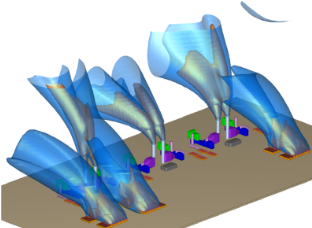

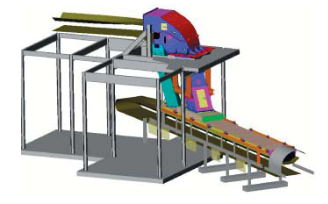

Coal Transfer Chute

Covered Conveyor Belts

Ore is often transported long distances on conveyors and through transfer chutes. Modeling provides information to minimize dust and maximize employee safety. Excessive dust can cause respiratory problems, and certain particulates such as coal can form an explosive mixture in air.

Ore Cars Carrying Product from Mine to Plant

Ore Cars Carrying Product from Mine to Plant

Rail cars take the ore from the mine to a port for transportation overseas or to another facility for processing. Trains many miles long bring coal to power plants to provide electrical power for millions of people. Reducing the drag of empty ore cars can provide significant fuel savings.

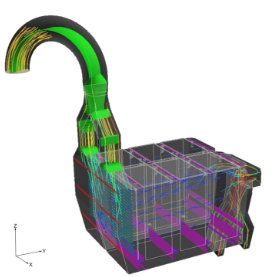

Electrostatic precipitators, baghouses, mechanical separators, and drop-out boxes remove particulate from a gas stream. Whether for pollution control from coal combustion or the gathering of material such as soda ash, ensuring a uniform flow through the collection region can maximize the amount of particulate captured.

Pathlines Through ESP

There are many applications of flow modeling in the mining industry. From the first stage of drilling and blasting to the delivery of the final product, CFD flow modeling can help reduce costs, improve performance, and increase throughput.

Learn more :