Optimizing Electrostatic Precipitator Design and Performance

By Kevin Linfield, Ph.D., P.Eng., P.E.

Electrostatic Precipitators (ESPs) are used to capture particulate from a gas stream and are a commonly used collection device for power generation, pulp and paper, mining, and cement plants. When designed and installed correctly, ESPs can collect up to 99% of particulate before discharging through a stack. However, incorrect design can result in lost product, increased fan usage, or particulate buildup that could threaten the structural integrity of supporting duct work.

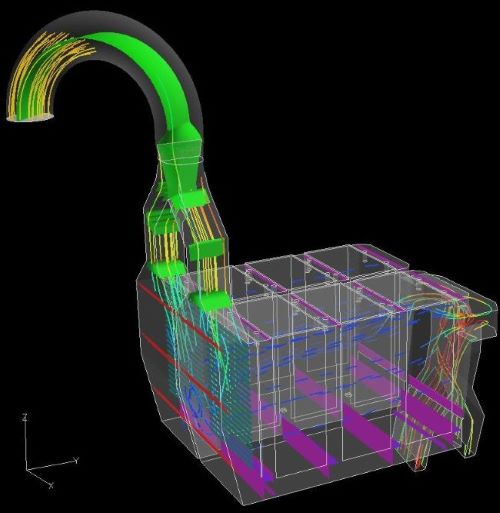

Computational fluid dynamics model of an ESP

An Overview of ESP Studies

At Airflow Sciences, we use flow modeling, physical modeling, and field testing to ensure optimum ESP design and performance. Modeling is often done during the initial design phase, but both modeling and testing can be performed on an existing ESP. Combining the Institute of Clean Air Companies (ICAC) standards with manufacturing and final customer requirements, specific objectives of an ESP study will usually include:

- Ensuring that gas flow entering the inlet nozzle and each chamber is well-behaved

- Minimizing pressure losses throughout the system

- Ensuring an equal flow split of gas and particulate to each chamber

- Ensuring proper mixing and interaction between any sorbent and gas

- Minimize ash deposition

The end result of the process is usually the design of flow control devices, such as perforated plates, vanes, and baffles, that can optimize performance and avoid costly problems. Physical and computational fluid dynamics modeling are useful tools in the analysis and optimization process, which can be used independently or together.

Physical model of an ESP in the Airflow Sciences lab

Field Testing to Determine Velocity Profiles

The velocity profile within an ESP is critical to collection efficiency. While the profile can be predicted through flow modeling, it may be more cost-effective and less time-intensive to determine it through field testing. By traversing a vane anemometer through select gas passages in the ESP, a full velocity profile can be established. The results of this testing can be used to determine chamber-to-chamber flow splits and identify high-velocity regions that contribute to poor capture efficiency.

With Airflow Sciences' engineering team, you can be confident that your ESPs are optimized for maximum efficiency and cost savings. Contact us today to learn more about how we can help optimize your ESP design and performance.

Learn more :