Rotary Air Heaters and Thermal Mixing

By Kelly Hile

Innovative CFD Solutions for the Power Industry

Rotary air heaters (or air pre-heaters) have been used for many years in the power industry to improve efficiency and reduce fuel consumption. In a power plant, the boiler or steam generator represents a large share of the energy use. The purpose of a rotary heater is to extract heat from hot flue gases and use it to pre-heat the cold air that feeds into the boiler. This improves the thermal efficiency of the boiler and significantly reduces the amount of fuel needed to operate the power plant.

Proven Experience Solving Flow Problems at Power Plants

Airflow Sciences has a long history of serving the power industry through field testing and modeling using Computational Fluid Dynamics (CFD). We have experience modeling nearly every component of a power plant, including rotary air heaters. When creating a numerical model that includes a rotary heater, engineers often assume a uniform temperature of the flue gas exiting the heater. Even though this assumption can conveniently simplify the model, it is problematic when the processes downstream depend highly on temperature.

Analysis on Rotary Air Heaters Using Azore

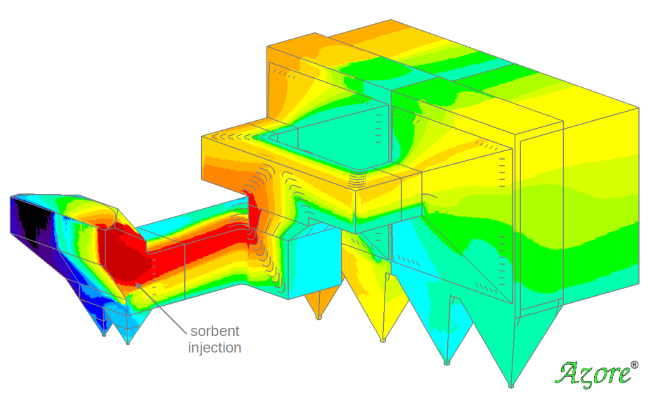

Using our in-house CFD software, AZORE®, we are able to create a UDT (user-defined task) to impose a rotating boundary condition on the heater and thereby model the rotational effects on temperature. We conducted an analysis like this for a U.S.-based power plant, which showed just how much the temperature of the flue gases can vary. In this plant, the thermal mixing made it difficult for pollutants like SO3 to be removed effectively in the downstream sorbent injection process.

Thermal mixing downstream of the rotary air heater

With information like this, power plants can make process improvements that benefit both the environment and their bottom line.

Airflow Sciences is continually driving innovations in CFD technology. Our software, AZORE®, is an affordable, state-of-the-art CFD software for modeling fluid flow and heat transfer in 3D simulations. We also develop custom software tools (UDT/UDFs) that can be used with AZORE® or to increase the capability of other CFD platforms like ANYSYS Fluent.

Interested in learning more about thermal mixing using CFD modeling? Watch out Vblog here.

Learn more :