How Engineers Bake Pies: Optimizing Commercial Bakeries with Computer Simulations

By Andrew Banka, P.E. and Kelly Hile

When fluid dynamics is applied to commercial baking, it means more consistent products and less food waste.

The famous chef Julia Child wasn’t afraid to mess up in the kitchen. “The grand thing about cooking,” she remarked, “is you can eat your mistakes.” While this might be true in your own kitchen, the concept of “eating your mistakes” takes on a whole different meaning in the commercial food business. When you sell what you bake en masse, your customers don’t want to eat your mistakes. Instead, commercial bakeries must swallow a hefty cost and take a bite out of profit margins for each baking cycle that goes awry.

For one commercial bakery, the mistake was pie: tray after tray of pies that were half-burnt and unsalable (as seen in the video on the left). With a problem on this scale, a bakery needs more than adjustments to oven temperatures or baking times. The typical methods of finding solutions by trial-and-error are not only time consuming, but also put a bakery at risk of even higher levels of product loss. Instead, forward-thinking companies are turning to Computational Fluid Dynamics (CFD) to innovate and solve problems.

Applying Computational Fluid Dynamics to Achieve Uniform Baked Goods

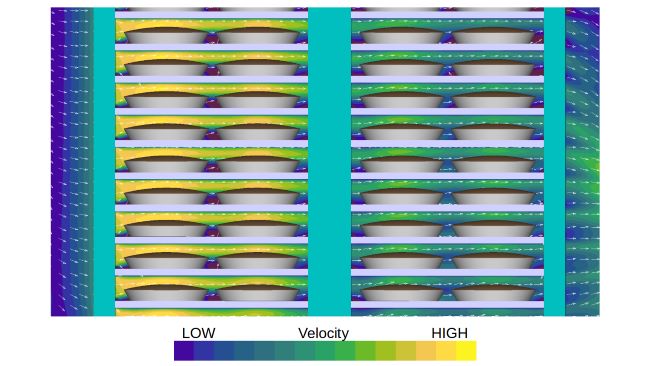

A CFD model simulates air flow and thermodynamics and calculates the air velocity, temperature, and humidity at any location inside the equipment. In this case, the numerical simulation enabled us to get a closer look at the flow patterns inside the pie oven. The image below shows the air velocity by color around the pies, with yellow zones indicating high velocity.

The simulation also calculates the temperature experienced at any given place in the oven. For one of the racks in the center of the oven, an animated pathline image shows both the direction of flow and the air temperature by color. The air is much hotter on the left side of the oven, which has caused uneven cooking. Even though the entire rack rotates, the pies toward the outside of the rack will experience much hotter temperatures than those in the center of the rack.

These numerical simulations can do more than identify problem areas in equipment. CFD also provides a way to evaluate modifications in a virtual environment, allowing this bakery to experiment with virtual burnt pies instead of real ones. A number of engineering solutions could be tested in the model to find the most cost-conscious and effective fix.

How does a commercial-grade, high quality oven result in undesirable products? It's not usually a question of the oven quality. Even the best oven manufacturer cannot optimize an oven for every possible product or load a bakery might use. This is another reason why CFD analysis is so valuable to food manufacturers, helping them to truly optimize each baking event and make the best use of the equipment at hand.

How ASC Works with Food Processing Clients

Airflow Sciences has been using CFD for over 40 years to fine-tune manufacturing operations for big-name food companies. Our unique knowledge of fluid dynamics, thermodynamics, and food processing helps us to improve the performance of equipment that depends heavily on fluid flow, such as ovens, dryers, roasters, and mixers. By predicting flow and temperature at all locations within the equipment, we can detect hot and cold spots, optimize batch times, test varying load conditions, and even determine pasteurization levels.

These days, pleasing customers is about more than a great recipe, and food manufacturers must design around a host of factors, including visual appeal, uniformity, and pasteurization. We put the powerful tool of CFD into the hands of food manufacturers so that they can achieve consistent product quality, prevent food waste, optimize equipment, and increase profit margins.

Talk to us today about how we can help fine-tune your food production process.

Learn more :