Indoor Agriculture: Using Virtual Grow Rooms to Increase Yield

By Kelly Hile

The use of indoor grow rooms in agriculture is on the rise. Safe indoors, plants can grow 24 hours a day, 365 days a year, regardless of outdoor climate. In these buildings, any needs of the plant can be furnished artificially, from light, to temperature, or even wind flow. Each parameter can be modified in an effort to create the most efficient, productive growing environment.

ASC’s Engineering Solutions for Indoor Agriculture

Airflow Sciences helps growers optimize their facilities so that they can achieve higher yields and protect their crops from indoor hazards, like inadequate airflow and low CO2 levels.

Computational Fluid Dynamics Applications for Grow Rooms

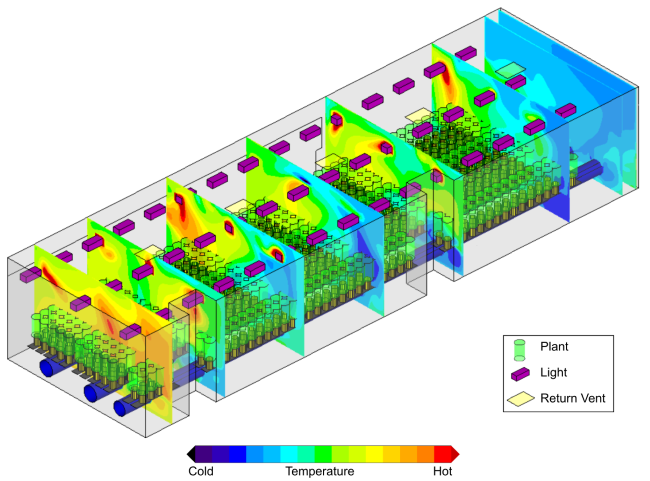

Our engineers are skilled in Computational Fluid Dynamics (CFD) modeling, where we take a digital version of the grow room and numerically model all of the various parameters in the space, such as temperature, pressure, humidity, and air flow rate. We include key climate control features (fans, light, vents, etc.), allowing us to provide an in-depth look at multiple variables in every location of the room. Design features in a new or existing grow room can be explored in a virtual environment, helping growers achieve an overall room design that is optimized for both efficiency and maximum growth.

Our models are based on the physics of flow dynamics and can highlight problem areas in the room, such as zones with stagnant air or high/low temperatures. From there, we help growers test design modifications virtually, before investing in costly equipment.

In this grow room, we found that the temperature varied throughout the growing area, with some areas cooler (blue/green) and some warmer (orange/red). Creating a more uniform temperature throughout the room will ensure crop uniformity and prevent damage from hot and cold zones (microclimates) or temperature swings.

Field Testing at Your Facility

Beyond CFD modeling, we use state-of-the-art testing equipment to measure flow, temperature, and other parameters at key locations. This can validate the room’s current monitoring technology and determine if the HVAC system is effectively meeting indoor climate targets.

Laboratory Services for Indoor Agriculture

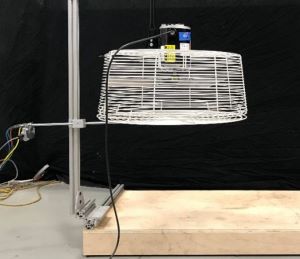

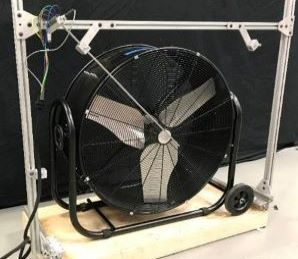

In the Airflow Sciences lab, we test equipment used for indoor climate control, such as fans, filters, air conditioning components and humidity control systems.

These fans are set up for testing in the Airflow lab. Using a specialized velocity probe, we characterize a fan’s flow rate and velocity profile, ensuring that new grow rooms will be equipped with the ideal size, number and type of fans. Fan testing results can be used in subsequent CFD models, where we evaluate the room’s predicted airflow based on fan location and type.

Climate Control for Indoor Agriculture

Proper airflow is one of the most critical aspects of indoor growing. Sufficient flow is necessary so that stagnant (CO2-deficient) air does not hang out around the leaf surface, hindering respiration. The movement of air also makes plants hardier, resulting in stronger stems and leaves. Even the particular angle of the flow hitting the leaf can make a difference in growth. The flow angle impacts transpiration, the expelling of water from the leaf surface, which is important for the self-regulation of temperature and for water transport within the plant.

One thing a grower never wants to do is lose control over the grow room environment, and the risk of losing crops is too high to attempt trial-and-error fixes. Our engineering solutions are customized to your unique grow room and climate control system. Contact us today to discuss your unique flow modeling needs.

Learn more about our work for indoor grow rooms:

Learn more :