Using Computer Simulations to Improve Drying for the Food Industry

By Andrew Banka, P.E.

This material was originally prepared for the International Drying Symposium as part of the USDA/CARD Drying Workshop and presented in June 2022 by Andrew Banka, P.E..

Airflow Sciences has worked with several well-known food brands to solve their operational challenges through computer simulations. We apply the methods of Computational Fluid Dynamics (CFD) to the food industry by creating virtual simulations of both air and heat flow in food processing equipment. CFD allows us to optimize equipment and validate design modifications in a virtual environment, helping food companies achieve both process efficiency and product quality.

Today we are sharing two real cases where we used computer modeling to improve drying performance. An effective drying process depends heavily on proper air flow and the balance of key parameters like temperature and humidity of supply air. Modeling can help with optimizing problematic equipment or with finding the ideal operating conditions for a given product.

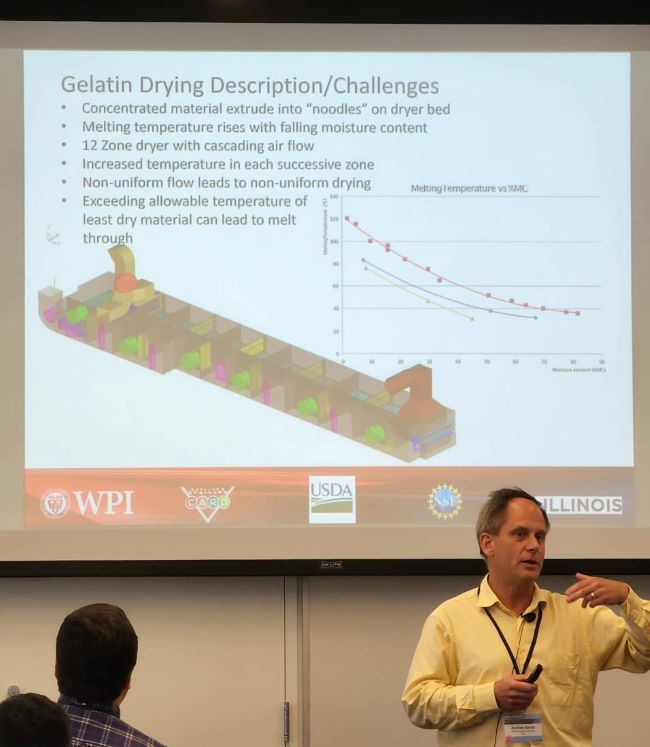

Case 1: The Gelatin Dryer

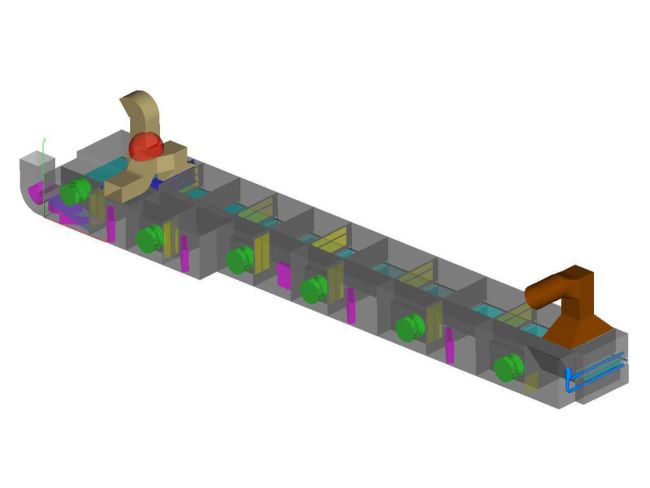

The Equipment: A large, multi-zone dryer, with each zone increasing in temperature and humidity to prevent premature melting of the gelatin product. Fans (shown in green) are in place to move air through the product bed.

The Goal: The manufacturer wants to speed up production, but too many defects occur when attempting to increase throughput in the dryer unit.

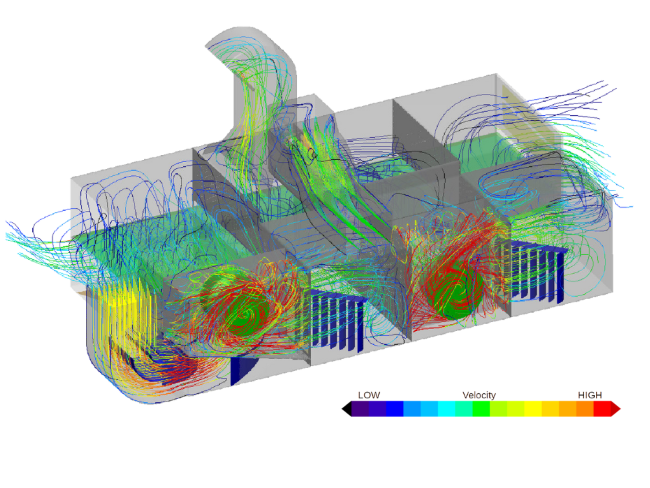

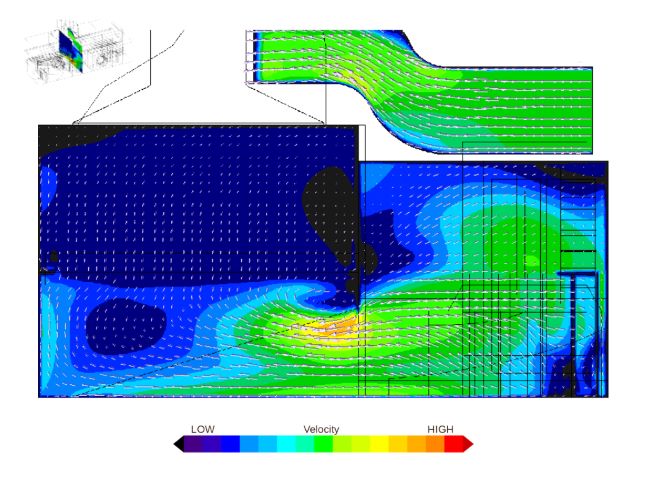

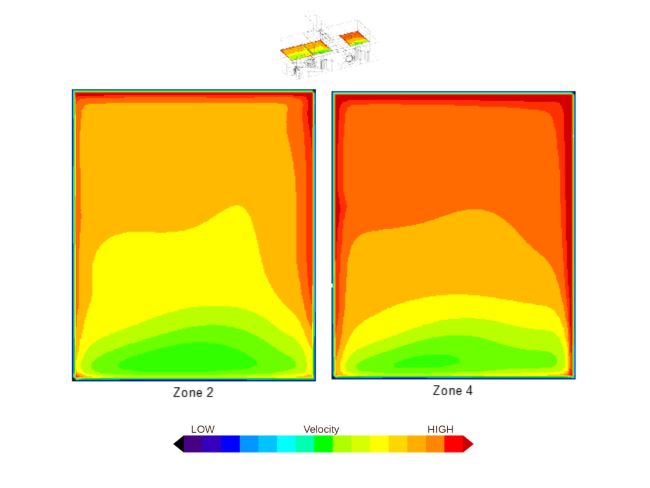

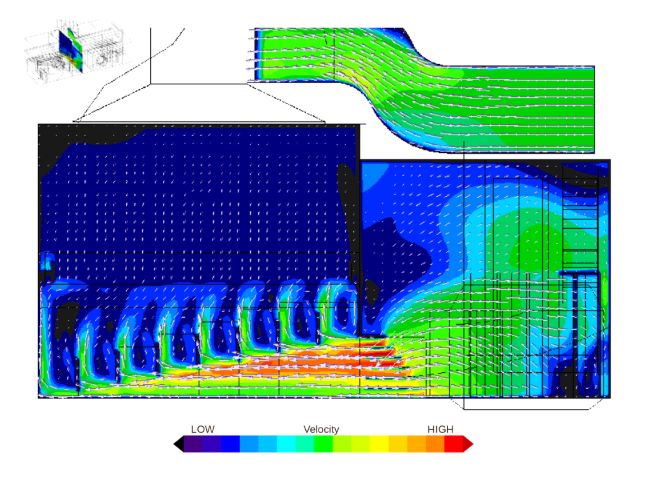

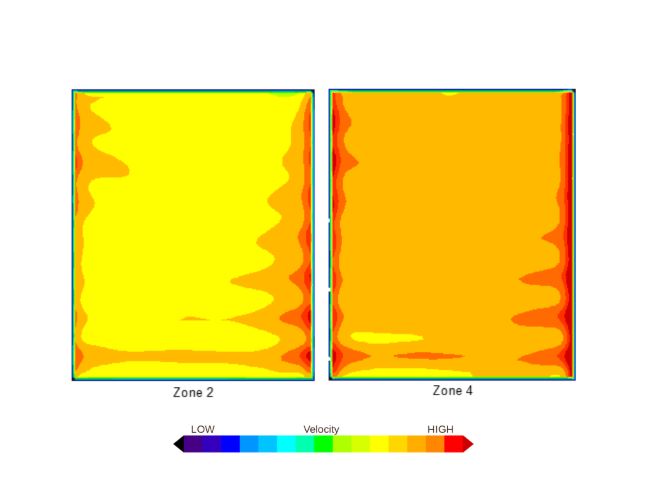

The CFD Results: Defects observed in the product bed correspond to areas of low air velocity in the simulation. The results show that the existing flow control devices are ineffective at regulating the velocity. Due to velocity variations, previous operational points were set to accommodate the slowest drying portion of the product bed. This led to the dryer being the slowest unit operation on the production line, limiting overall production rate.

We simulated the flow patterns for a dryer model with modified flow control devices. The results predict a more uniform flow through the product bed, at a higher velocity that will increase the drying rate. The speed of the product line can then increase without defects or premature melting. After installation of the recommended modifications, the dryer became the fastest unit operation in the production line.

Case 2: The Pistachio Roaster

The Equipment: A bed dryer for roasting pistachios with three zones, the first two zones at independent temperatures, and the third zone for cooling.

The Goal: Optimize the operating parameters of the dryer zones for product quality, including nut moisture content, color, texture, and pasteurization.

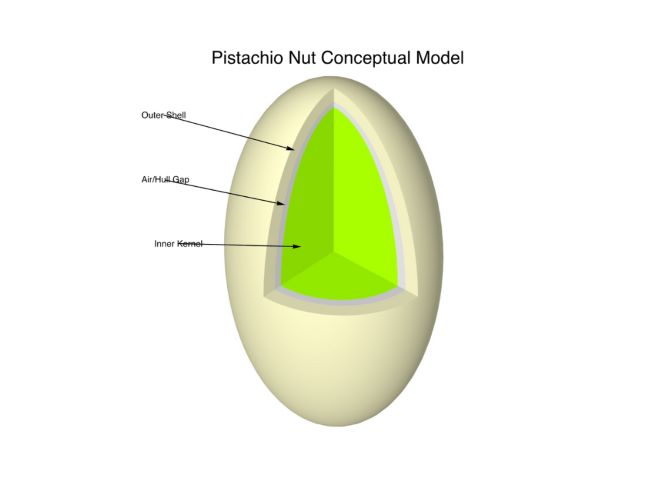

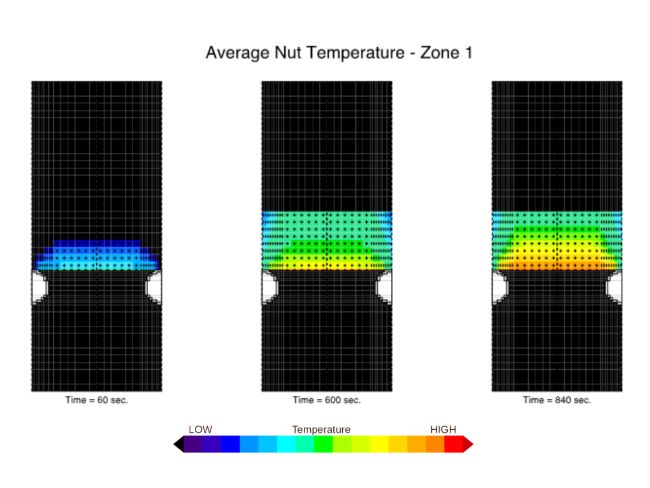

The CFD Results: We used a multi-scale modeling approach to simulate the roasting process, using a micro-model of the nut itself and a macro-model of the dryer zones. The advantage of combining models of both product and equipment into one simulation is that the interaction between the product and the process equipment can be fully coupled. Incorporating micro-models into CFD simulations can also be used to assess changes beyond temperature and moisture, such as pasteurization, browning, and case-hardening.

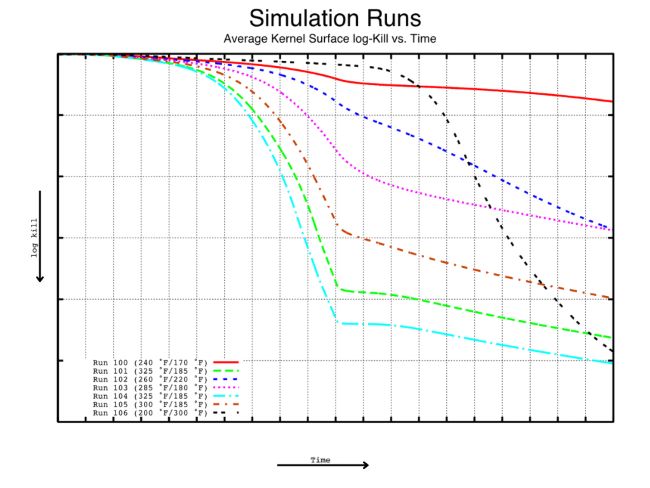

The two models were used to assess various operating conditions, enabling the process to be optimized by temperature and residence time in each dryer zone. Any combination of operating conditions can be simulated to determine the direct effect on the product. The CFD model provides data such as air temperature, air humidity, nut temperature, moisture content, and air velocity.

Since the CFD simulation predicts temperature over time, pasteurization models can be applied to establish the rate of microbial death. Pasteurization (indicated by log-kill) will depend on the location of each individual nut within the bed, since the time-temperature history for each one will be different. The simulation provides a way of ensuring that all of the product is fully pasteurized.

Multi-scale modeling is a smart choice when the process equipment is much larger than the product being assessed, and when information is needed on both large and small scales.

Learn more :