Managing Battery Temperature with a Targeted HVAC Design

By Jeff Everett and Kelly Hile

Using CFD technology to bring storage solutions to life for the power industry

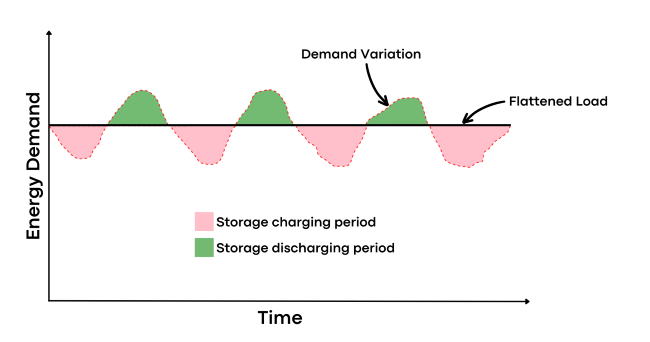

As the power industry continues to investigate and develop new technologies in energy generation, one design challenge is the availability of reliable energy storage. Demand for electricity is highly variable and influenced by numerous factors, which can make it difficult for utilities to optimize their generation output. One solution is “load leveling,” in which generation units run at a more consistent (and efficient) output, and surplus energy is stored when demand is low. When demand increases to peak levels, the stored energy can be discharged.

Load leveling helps utility providers respond to variations in energy demand

Potential Hazards Associated with BESS

A battery energy storage system (BESS) is one method to store surplus energy and respond to variable demand. However, one characteristic of a typical BESS is that battery temperatures increase significantly during peak discharge cycles, which could lead to unit failure or even a fire. Careful thermal management is essential to avoid overheating. For indoor facilities this means that the HVAC system must be capable of delivering cool air to the batteries to keep the modules at acceptable working temperatures.

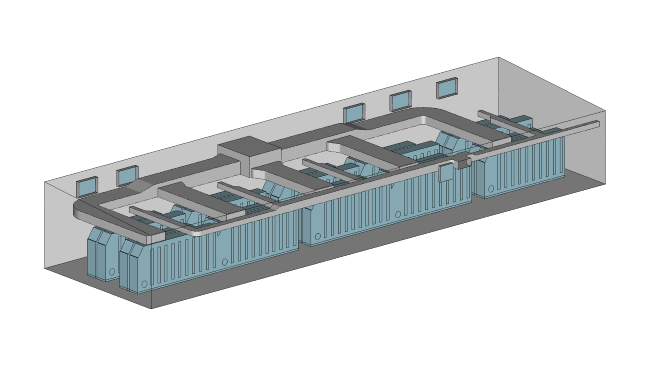

Proper ventilation in an indoor battery storage facility ensures safe and efficient battery operation

BESS Facility Design

Airflow Sciences engineers recently collaborated on the design of a new BESS facility where thermal management was a concern. In order to evaluate the ductwork design and the cooling capacity, the design analysis included a computer simulation of the room ventilation system using Computational Fluid Dynamics, or CFD. This technology utilizes high performance computing and proven numerical methods for predicting air flow and thermodynamics in a three-dimensional computer model.

The team started by constructing a CAD model of the BESS facility interior, which included the racks of BESS modules, the HVAC ductwork, and the cooling air outlets and return duct openings. Each group of battery racks is mounted inside a cabinet with its own internal cooling fan that pulls room air in through an octagonal opening, then exhausts the heated air out through a series of vertical openings adjacent to the racks.

A three-dimensional CAD model of the battery storage room

Exploring the Air Flow

Next, the three-dimensional space in the CAD model was divided into millions of computational cells, called a mesh. Airflow engineers approach each model geometry uniquely, targeting the mesh generation to support the particular questions being explored by the CFD study. An expertly developed mesh means more accurate results, faster simulation time, and reduced computational error.

A simulation of air flowing throughout the room was conducted with the CFD software, Azore®. Azore takes into account the temperature and velocity of the air as it enters the room through the HVAC system, and follows the flow as it enters and exits the battery units. The return air vents pull warm air out of the room and back into the cooling system. Throughout the room, Azore incorporates the thermodynamic effects of the flow, calculating the temperature changes to cooling air as it warms up inside each battery cabinet. In addition to the heat load of the battery modules, heat transfer into the facility from the building roof and walls was included to account for the high outdoor ambient temperatures at the facility’s location in the southwest US.

Cold air (blue) feeds directly to the equipment intakes

The temperature of the exhaust air leaving each cabinet was dictated by a User-Defined Function, or UDF, a customization tool in Azore. Airflow Sciences developed the UDF to address the unique physics of this battery set-up. With a customized UDF, the exhaust temperatures were accurately represented while keeping computing costs reasonable for the client.

Benefits of CFD Modeling

The CFD simulation predicts the air velocity, flow direction, and temperature at any location within the room. With these results in hand, the team was able to explore the room HVAC design in new ways. HVAC simulations can reveal room hot spots or system energy waste due to recirculation or bypass air. Ultimately, the outcome of performing CFD analysis is a more effective design. A successful simulation enabled the construction of this new BESS facility to proceed with confidence.

Watch the video of the CFD simulation results below and see the battery storage room HVAC system in action!

At Airflow Sciences, we are focused on putting the very best of fluid dynamics tools into the hands of today’s industry leaders. Contact us to learn more about how a customized CFD strategy can target the unique challenges of your organization.

Learn more: