Clean rooms used in pharmaceutical manufacturing operations use downflow of

Clean rooms used in pharmaceutical manufacturing operations use downflow of

HEPA filtered air to ensure sterility. While experimental methods can be used to

detect regions of upward flow which can potentially transport contaminants up to

the product level, modifications to an existing clean room will affect cost and

start-up schedules. CFD offers an alternative to assess and correct system

design at the concept stage, when those modifications have a smaller effect on

project budget.

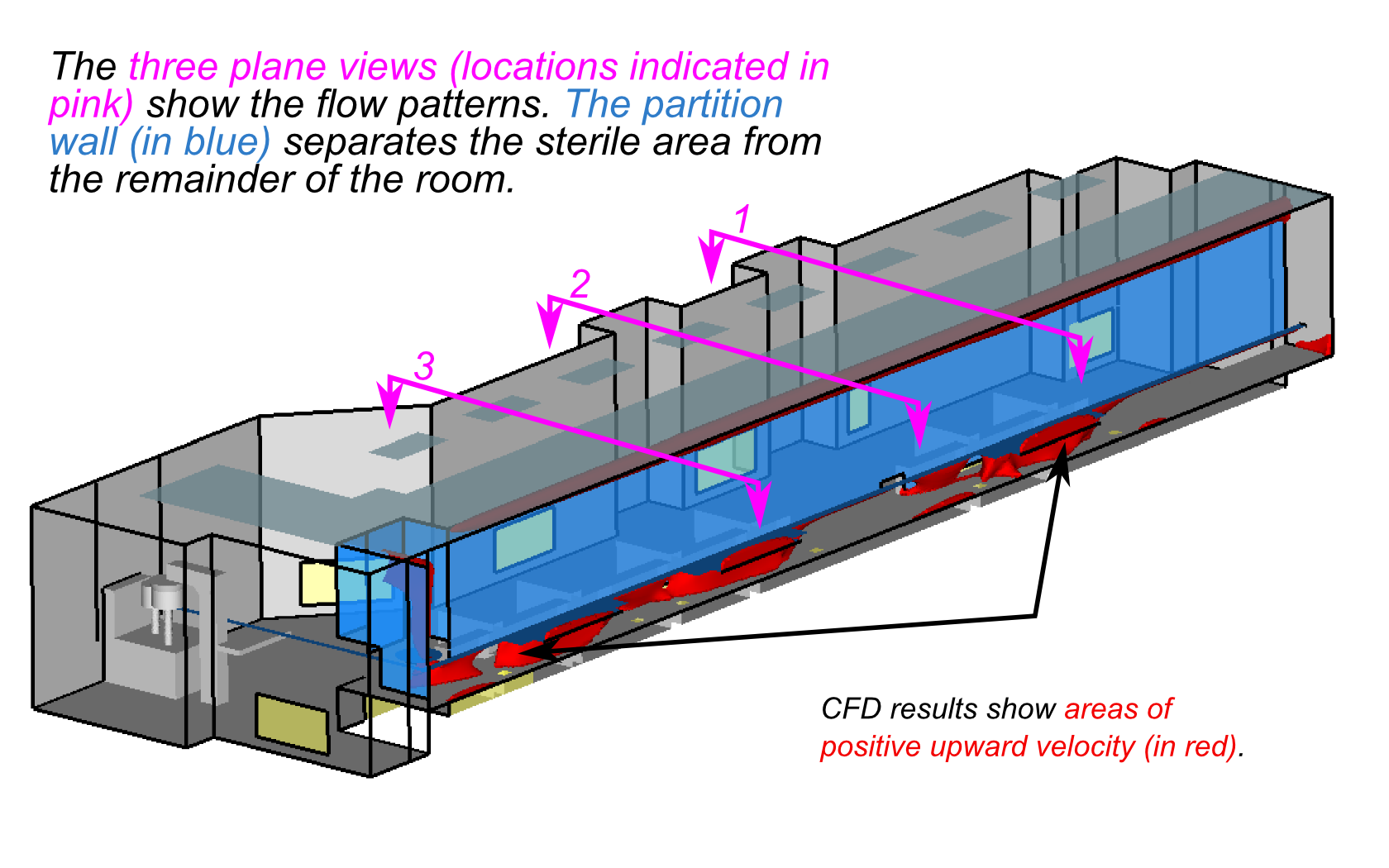

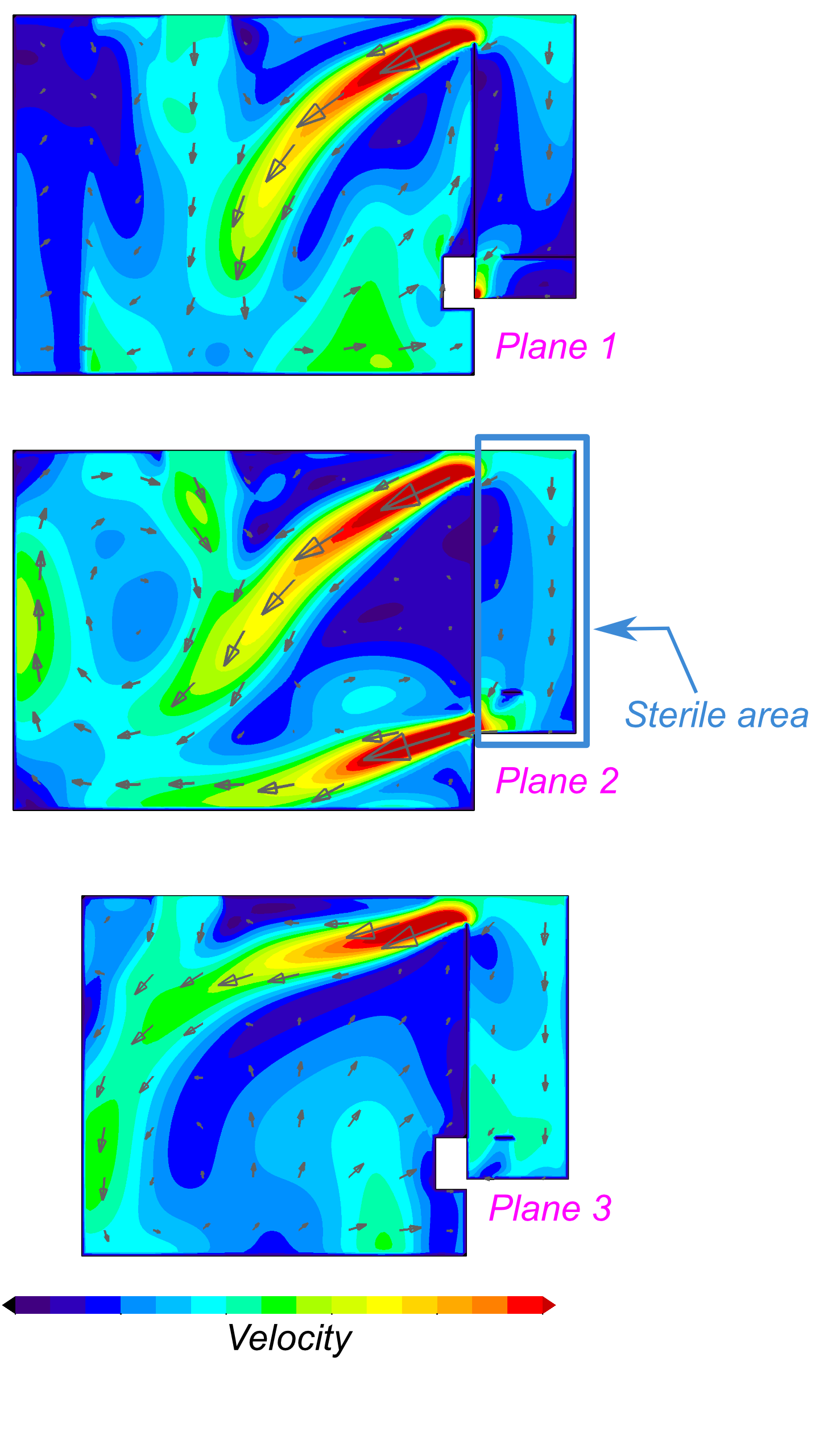

The images below show the analysis of a clean room that was slated for

increased capacity, including additional product equipment and revision to the

return air register locations. CFD analyses showed that the proposed changes

did not significantly affect the flow patterns in the critical regions of the clean

room, allowing the modifications to proceed with confidence.