Intensive Quench

Intensive Quenching achieves high surface compressive stresses through the use of plain water at high velocities. With this technique, it is possible to achieve the same hardness using low-alloy steels as are achieved through normal processing of alloy steels, providing cost savings.

In order for Intensive Quenching to work properly, specific water velocities must be provided to the part surface. Computational Fluid Dynamics (CFD) can be used to ensure that the quench fixture design will provide the required velocities, avoiding costly experimental trials.

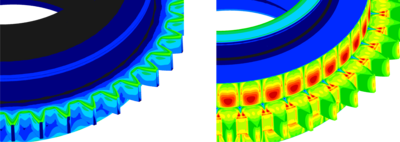

Below are the convective heat flux rates developed on a test gear for two different quench fixtures, one with flow in the axial direction, and the other featuring radial flow.

Axial flow (left) Radial flow (right)

Axial flow (left) Radial flow (right)