Optimize Your SCR, ESP, and other Equipment for Compliance with the Good Neighbor Plan

Airflow Sciences Corporation's proven simulation and testing expertise has improved performance of hundreds of ESPs and SCRs, reducing particulate and NOx emissions, avoiding excessive ammonia consumption and saving on maintenance costs for over 45 years. We are using that same experience to partner with plants to improve air quality and protect communities.

What is the Good Neighbor Plan?

The EPA's Good Neighbor Plan is a program that encourages power plants, refineries, cement kilns, and paper mills to reduce their emissions of air pollutants that can harm the health of nearby communities. The program sets specific goals for reducing emissions of particulates, VOCs, sulfur dioxide and nitrogen oxide, which can cause respiratory problems and other health issues. Compliance with the Good Neighbor Plan is crucial for plants to protect the health of their neighbors and improve the overall quality of life in their communities. By reducing emissions, plants can help prevent health risks associated with air pollution, improve air quality, and maintain good relationships with the communities they serve.

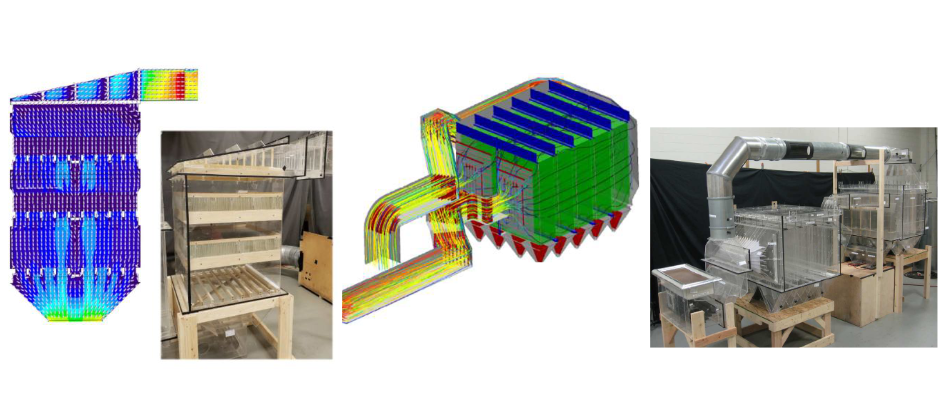

At Airflow Sciences, we are using our expertise to optimize SCRs, ESPs, RTOs, and other systems for compliance with the Good Neighbor Plan, ensuring you can meet your environmental responsibilities while maintaining efficient operations and avoiding hefty fines. Through CFD modeling and physical modeling, we are able to identify areas for improvements and provide optimized designs. Below are examples of SCRs and ESPs being evaluated through CFD modeling and tested in the Airflow Sciences lab, prior to implementation. In the field, we tune SCRs by manipulating the valves at the ammonia injection grid and inspect for pluggage using our state-of-the-art equipment. We also test ESPs, RTOs, baghouses, and duct systems for flow uniformity and balance. Together, we can develop a customized solution tailored to your plants unique needs.

Benefits of Optimizing Your Pollution Control System

- Maximize particulate capture

- Improve heat transfer and thermal performance

- Avoid excessive ammonia consumption

- Minimize potential for system pluggage by particulate matter

- Reduce maintenance costs and downtime

- Increase profitability, productivity, and efficiency

- Improve air quality in communities

Contact us today to get started optimizing your Equipment

Explore Our Engineering Services

CFD Modeling

![]()

We use Computational Fluid Dynamics (CFD) to improve process performance. CFD simulations can easily assess design modifications and predict flow, heat transfer and species concentrations throughout an entire system.

Field Testing

Our skilled engineers and technicians perform on-site testing at your facility with state-of-the-art testing equipment. Services include SCR tuning (NOx, NH3 slip), online video inspection (LPA pluggage), 3D flow measurement, and conducting tests using standard EPA methods.

Lab Testing

![]()

We create custom lab-scale models to evaluate a new or existing systems. In our lab, we can test a variety of flow conditions and scenarios including ammonia injection. Lab testing can be combined with CFD modeling to investigate a process even more thoroughly.