Climate Controlled Buildings and Rooms

ASC has extensive experience in modeling and testing HVAC systems. We also have worked with our clients with challenging humidity and temperature requirements within warehouses, server rooms, manufacturing floors, and BESS units.

Recent Projects

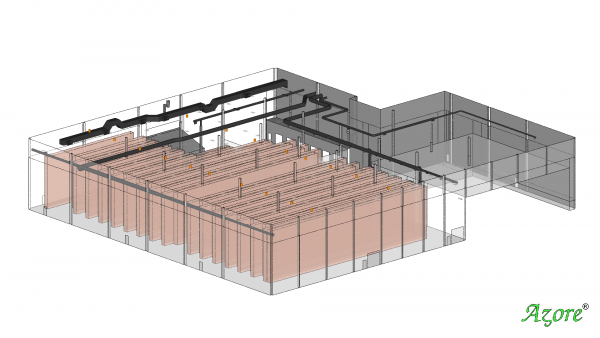

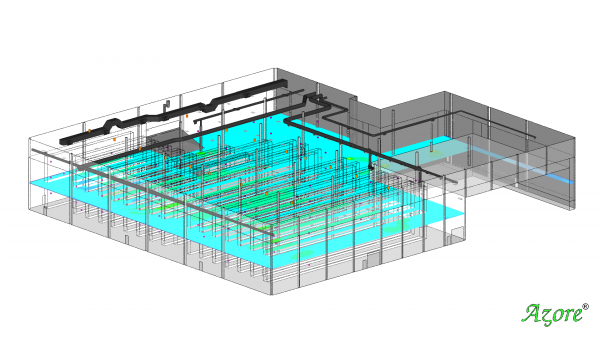

HVAC Design for Medical Product Warehouse

Climate controlled warehouses have maintained conditions to protect temperature sensitive equipment and products. These facilities use HVAC systems to regulate the temperature, humidity, and air quality.

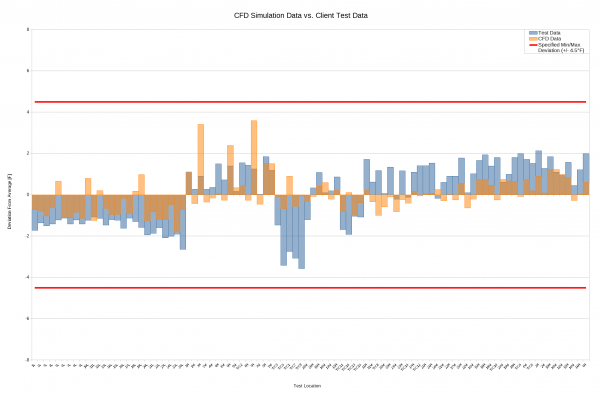

ASC engineers were tasked with the challenge to maintain temperatures over a large foot-print building with 70' height to within +/-4.5oF so that stored medical products do not experience adverse temperatures, resulting in spoilage or product failure due to degraded ingredients.

|

|

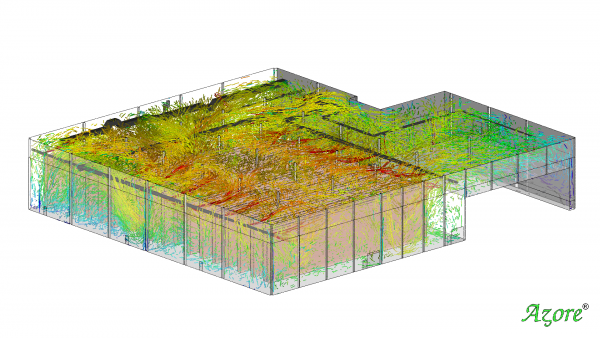

| CAD Geometry of warehouse | CFD Streamlines Colored by Velocity |

|

|

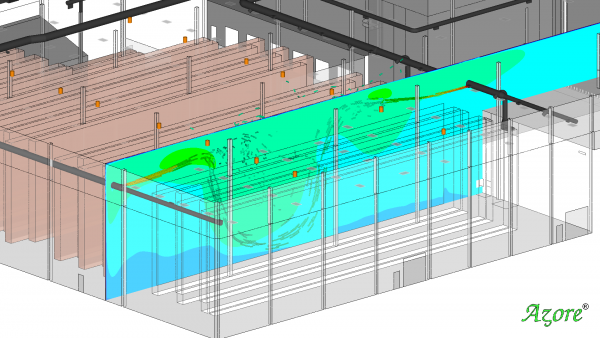

| Detailed view of flow discharge from supply ducts (depicted by streamlines). | Detailed view of flow discharge from supply ducts (depicted by streamlines). Temperature contour plot at mid-elevation plane. Note magenta dots - these are locations where field test data was measured to compare to CFD results. |

Through CFD modeling, ASC was able to verify that the temperatures were within the target +/-4.5o goal throughout the entire building as seen in the chart below.

The electronics housed in data centers, battery storage buildings, and bitcoin mining rooms can produce considerable amounts of heat. These facilities require well-designed air cooling systems to keep the servers and computer components from overheating.

Electronic Cooling Room Design - The Space Fence

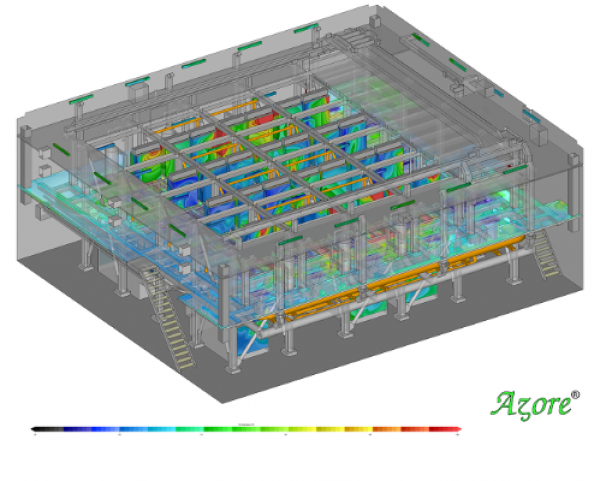

ASC was proud to partner with the USAF and USSF to optimize the design of the HVAC system for the Space Fence, a radar installation to detect small debris in the Earth's orbit.

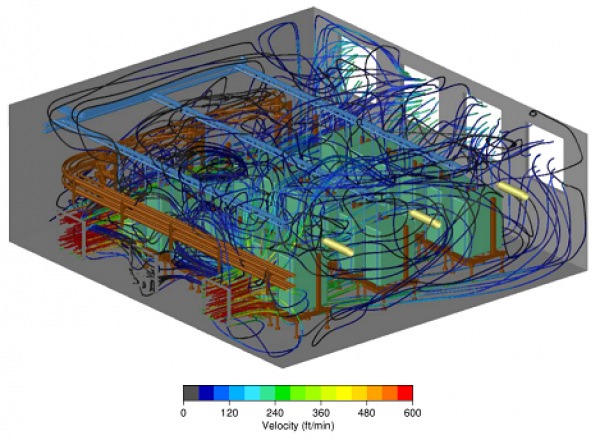

A complex HVAC system was designed to deliver cool air to each element of the server arrays to maintain acceptable interior ambient temperature during operation. The server room was complicated by internal features that include structural members, floor grating, piping, electrical components, and the HVAC air handlers, ductwork, intakes, and exhausts.

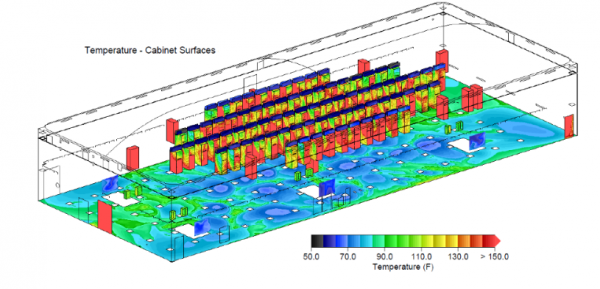

During a baseline CFD analysis, it was found that preliminary arrangement of the HVAC outlets underneath the radar electronics was not optimized. To correct this, the HVAC ductwork was repositioned and re-designed to concentrate the outlets mostly within the radar array, with some retained outside of the array to provide cooling air to auxiliary electronic cabinets.

|

|

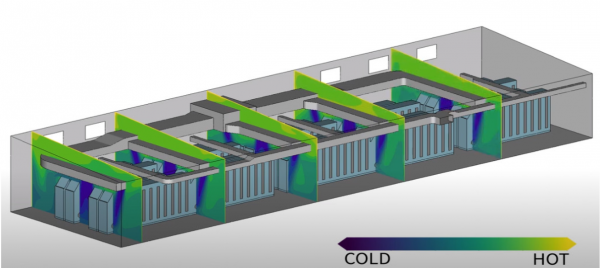

| Transmit (TX) Building CFD Model Results - Velocity Patterns | CFD Model Showing Temperature of Cabinet Surfaces in the RX |

Electronics Cooling Room Design - Data Center Example

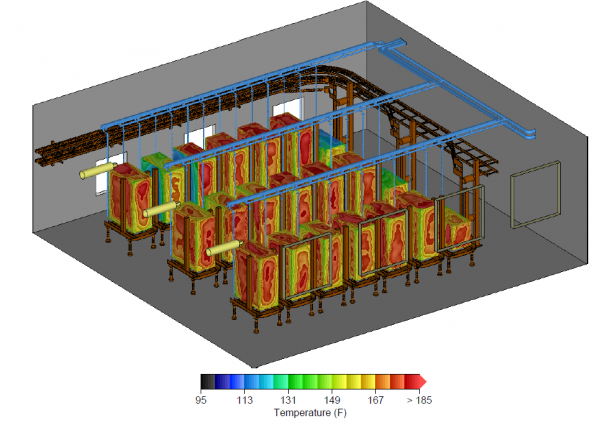

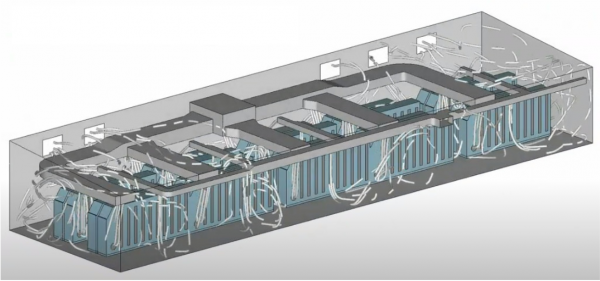

In the example below, ASC used CFD modeling within a server room to avoid temperatures greater than 110oF.

|

|

| Temperature on Surface of Servers | Flow Streamlines |

Battery Energy Storage Systems (BESS)

Battery Energy Storage Systems, or BESS, are a method to store surplus energy. These units experience a significant amount of heat as the batteries charge and discharge. While fans are typically present, they are usually on one side of the enclosure, causing heat to be intense on the other side.

|

|

| Air Temperature by Location | Flow Streamlines |

ASC engineers were approached regarding an inefficient HVAC system in a BESS. Using flow modeling, ASC was able to predict conditions within the unit. Flow results were plotted and analyzed as contours of velocity, temperature, and pressure. With this information, we helped eliminate hot spots and energy waste caused by recirculation or bypass air, ultimately optimizing the design and minimizing heat damage to the equipment. Take a closer look at our BESS airflow simulation in this short video.

For more information:

-

The Airflow Update Fall 2021: HVAC Design for Critical Cooling Applications

-

The Airflow Update Summer 2023: Using CFD Modeling to Design the HVAC System for the World's Most Advanced Radar

-

Airflow Sciences Blog: Managing Battery Temperature with a Targeted HVAC Design

-

Airflow Sciences Blog: Flow Modeling for Cryptocurrency Mining