This closed-loop tunnel was custom-designed to nestle into the Adaptive Structures Lab at Northwestern University. Professor Lucia Stein-Montalvo and her team are using this tool to study the interaction between architectural structures and wind.

Pictured with this powerful wind tunnel in the Airflow Sciences flow laboratory, ASC's Vice President Andy Banka,

Dr. Lucia Stein-Montalvo, and ASC's Project Engineer Kelly Hile.

Dr. Stein-Montalvo's research focuses on retrofitting shape-shifting structures in urban locations as a way to steer wind and provide shade in areas where air is stagnant and uncomfortable within modern cities. In one of her journal articles, it's noted that areas on the ground, called urban canyons, are prone to collecting and recirculating contaminated air.

A proposed solution comes from a variation of origami, called kirigami. This art form originates from the 17th century and involves folding and cutting paper to allow for a design to stand away from the page. By adding cuts to a rigid 2D surface, it can then buckle and tilt at the cut, causing it to become a flexible, 3D shape.

Illustration of the concept for kirigami-inspired wind steering.

Journal of Wind Engineering & Industrial Aerodynamics: Kirigami-inspired wind steering for natural ventilation.

Utilizing this art form, the team is developing adaptive ventilation systems for urban settings where structures respond dynamically to wind and offer not only fresh air circulation but also cooling shade in the canyons.

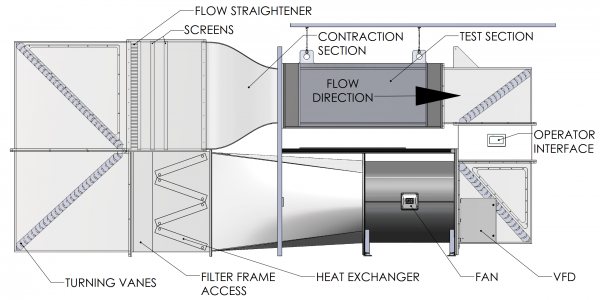

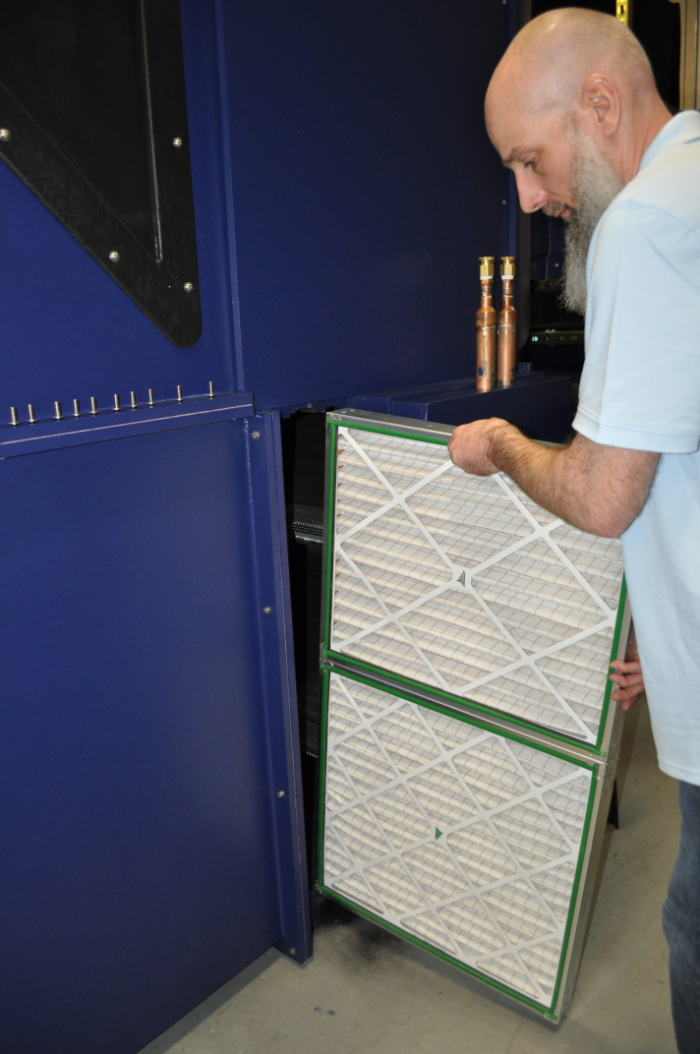

This is no off-the-shelf wind tunnel system. The engineers at Airflow Sciences designed this tunnel to specifically meet the velocity needs of the Adaptive Structures Lab, with highly uniform velocity in the test section and low turbulence levels. The test section is fully visible on all four sides and features a large removable panel on an overhead rail system, which offers complete access for setting up new models for testing. Since the research team plan to perform flow visualization with Particle Image Velocimetry (PIV), a modular filter system was worked into the system along with a port for particle seeding. An optical breadboard was incorporated beneath the test section so that cameras and other equipment could be easily secured into place.

This impressive wind tunnel was manufactured in the Airflow Sciences flow laboratory in Livonia, MI. The tunnel was fully assembled and tested onsite before our technicians transferred it to its final home in the Adaptive Structures Lab.

Dr. Stein-Montalvo and ASC's Kanthan Rajendran in the Adaptive Structures Lab.

KEY FEATURES OF THIS TUNNEL INCLUDE:

- Features a 2'x2' test section with full visibility that spans 5' long

- Able to reach speeds up to 40 meters per second for testing wind/structures interactions

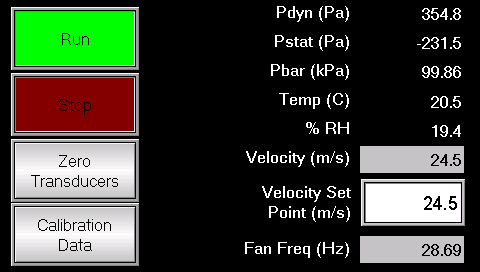

- Utilizes a variable frequency drive to control the velocity in the test section based on pressure, temperature, and humidity sensors

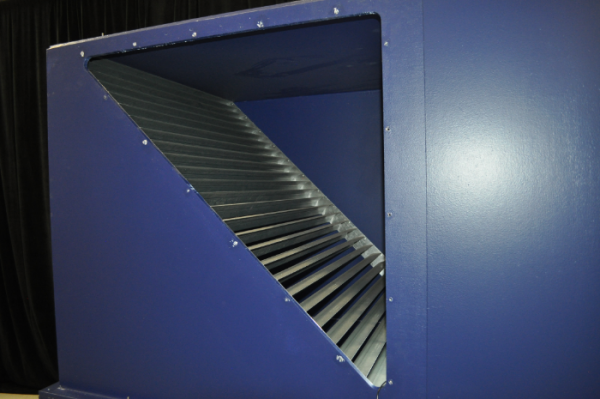

- Housed within are turning vanes, honeycomb matrix, and screens to ensure flow uniformity and provide a 0.5% turbulence level

- Contains modular filters to collect particles used for Particle Image Velocimetry (PIV)

- Includes an optical breadboard below the test section for PIV cameras and other equipment

Wind Tunnel Components

|

|

|

||

| System Fan with Vibration Reduction | Optional Filter System for Collecting PIV Particles | Honeycomb Matrix |

|

|

|

| Turning Vanes at Each 90 Degree Turn | Touchscreen Interface for Setting Velocity |