CFD "Cements" Plant Efficiency

By Wendy Beale and Kevin Linfield, Ph.D., P.Eng., P.E.

Cement is the key ingredient of concrete, the most widely used material in construction. Some cement plants, called integrated plants, often cover all the processing, from material extraction to a final product. This includes the crushing, grinding, heating and cooling, and combustion - all within one site location. Other plants, or grinding plants, only grind clinker (semi-finished product) to produce the final material. Both types of plants require engineers to provide modeling to ensure optimization within the plants, as well as confirming environmental emissions compliance.

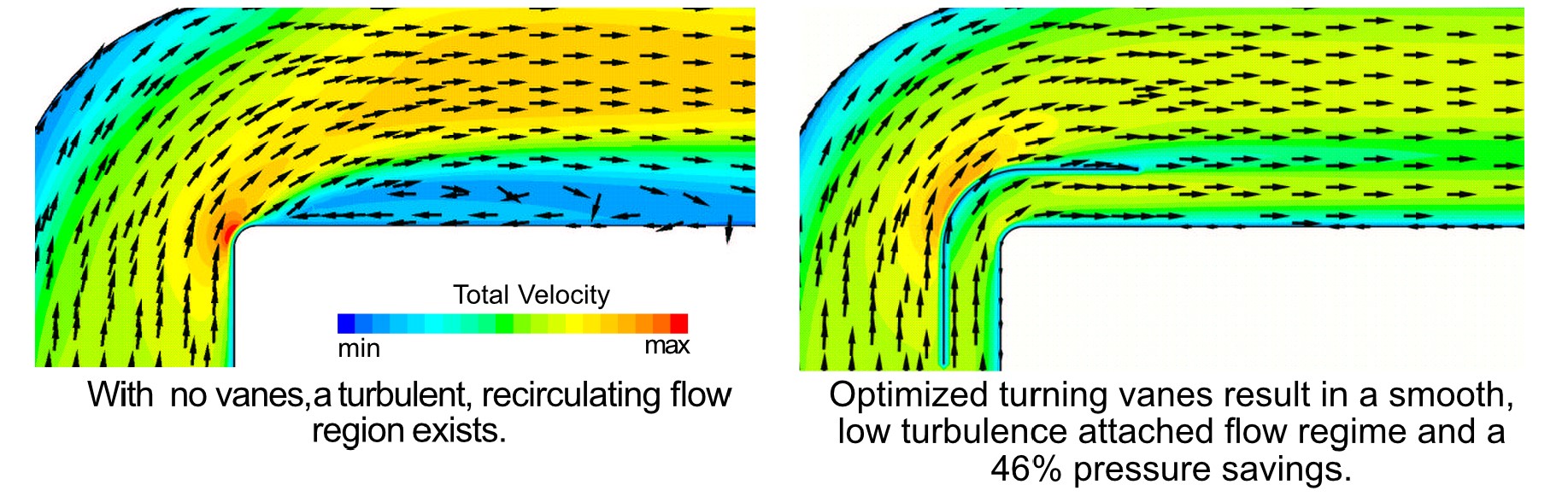

Computational Fluid Dynamics (CFD) modeling helps optimize system performance by potentially showing design flaws. Creating a CFD simulation of ductwork and fans, a visualization of flow fields can show where design improvements could be made for smooth, low turbulent flow and may result in pressure savings that can lower operating costs while improving efficiency.

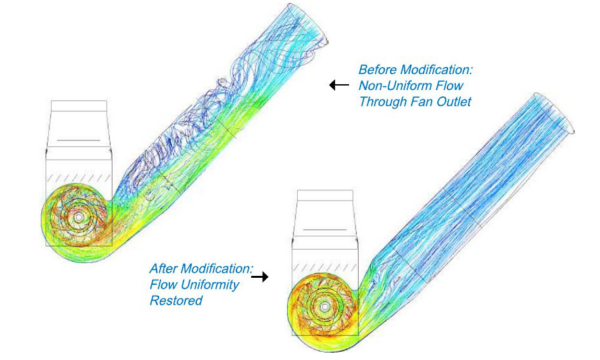

Air flow streamlines before and after modifications made to fan blades.

Since cement production deals with abrasives, erosion concerns can also be evaluated and addressed.

To reduce the environmental impact of the manufacturing of cement, CFD can be used within the pollution control devices such as fabric filters, cyclones, and ESPs. By visualizing the pathlines and pressure distributions, particle trajectories can be predicted and design changes can be implemented to maximize particle capture. The areas surrounding the plant also need to be considered for plume dispersion of gases and other airborne debris, modeling can track plumes to ensure that neighboring air intakes are not impacted.

***

Airflow Sciences Corporation (ASC) is a fluid dynamics solutions company, specializing in the design and optimization of equipment and processes involving flow, heat transfer, combustion, and mass transfer. Now celebrating 50 years as an industry leader, ASC has focused on testing and simulation of air, gas, liquid, and particulate flows since 1975.

ASC also manufactures standard and custom test equipment, including probes and wind tunnels, enabling customers to collect data accurately and efficiently. ASC offers comprehensive flow solutions and optimization and serves a wide range of industries including HVAC, power, auto, rail, and food processing.